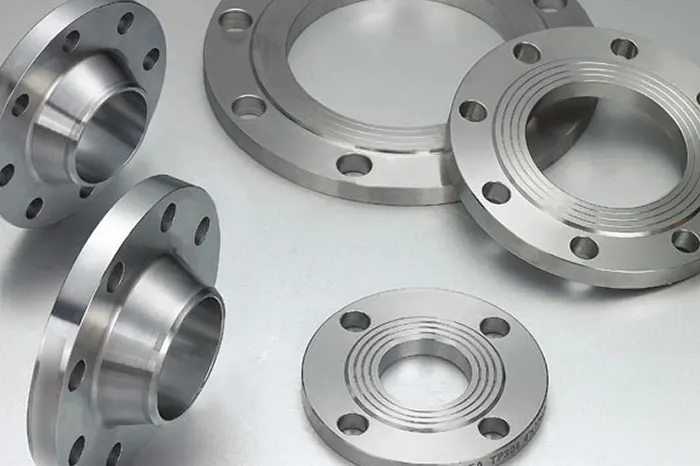

Alloy 20 Flanges (UNS N08020) are highly demanded in industries dealing with sulphuric acid and other aggressive chemicals. Designed as per ASTM and ASME standards, these flanges ensure superior corrosion resistance and excellent mechanical strength. Sunrise Industries manufactures Alloy 20 Weld Neck Flanges, Slip-On Flanges, and Blind Flanges in various pressure ratings and dimensions. Known for their durability and precision, these flanges are widely used in chemical, pharmaceutical, and power generation industries. With custom manufacturing facilities, we supply Alloy 20 Flanges worldwide, ensuring reliable performance, safe connections, and long service life in critical piping systems.

Alloy 20 Flanges Manufacturer & Supplier

ASTM B564 Alloy 20 Industrial Flanges Specification:

Grades : Alloy 20 (UNS 08020)

Standards: ASTM, ASME, ANSI, JIS, DIN, BSNA 11, EN Ni 99.2, JIS NW 2200, GOST-НП-2, AWWA, Custom Drawings

Specifications: ASTM B 564 / ASME SB 564

Size: 1/8″ TO 48″ NB

Class: 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64.

Wall Thickness: From 2 to 40 mm.

Schedule: Sch. 5 TO Sch. XXS.

Type: Flat Face (FF), Raised Face (RF), Ring Type Joint (RTJ).

Form: Slip On (SORF), WNRF, Blind, Socket Weld, Orifice, WNRTJ, BLRTJ, Threaded, Groove & Tongue, Lap Joint, Square Flanges & As Per Clients Required.

Our Alloy 20 Flanges Fittings conforms to NACE MR0175/ISO 15156.

| Standard | WERKSTOFF NR. | UNS | GOST | AFNOR | OR | JIS | BS | EN |

|---|---|---|---|---|---|---|---|---|

| Hastelloy B2 | 2.4617 | N10665 | --- | --- | --- | --- | --- | --- |

| Grade | Ni | Mo | C | P | Mn | Ti | Si | Cu | Mb | Cr | N |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Hastelloy B2 | Bal. | 26.0 - 30.0 | 0.02 max | 0.04 max | 0.1 max | - | 0.1 max | - | 1.0 max | - | Bal. |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2% offset) | Elongation |

|---|---|---|---|---|

| 9.2 g/cm3 | 1370 °C (2500 °F) | Psi – 1,15,000 , MPa – 760 | Psi – 52,000 , MPa – 350 | 40 % |

| Incoloy 800 Precision Tubes Supplier in Tanzania | Incoloy Alloy 800 Rectangular Tubes in Nigeria |

| Incoloy 800H Seamless Pipes Exporter in Brazil | B514 Alloy 800/H/HT Square Pipes Exporter |

| Incoloy UNS N08800 Seamless Tubes in Madagascar | Incoloy 800 HT Square Tubes in Ethiopia |

| Incoloy 800 Werkstoff Nr. 2.4816 Welded Pipes | Incoloy 800 Hollow Pipes Supplier in Chile |

| Incoloy 800HT Welded Tubes Exporter in Egypt | Incoloy 800 Hollow Tubes Distributors |

| Incoloy 800HT Round Pipes Stockiest in Ghana | ASTM Incoloy 800/H/HT EFW Pipes in Zambia |

| Incoloy 800 ERW Pipes Manufacturer in India | Incoloy Alloy 800 EFW Tubes Dealer in Peru |

| Incoloy 800H ERW Tubes Stockholder in Africa | ASTM/ASME B515 Incoloy 800 Capillary Pipes |

| Incoloy 800 Alloy Rectangular Pipes in Libya | Incoloy 800HT Capillary Tubes in South Africa |

| ASME SB 407 Incoloy 800/H/HT Pipes/Tubes | ASTM B407 Incoloy 800 Pipes & Tubes in Algeria |

| Incoloy 800 ERW Pipes Manufacturer in Qatar | N08800 Polish Bright Pipes Suppliers in Kuwait |

As your one-stop manufacturing partner, Sunrise Industries maintains a complete inventory of ready-to-sell raw materials alongside custom parts fabrication and full engineering services. From prototyping to production, we provide everything at a single location—serving all industrial sectors and transforming manufacturing value chains.