35+ materials & 8+ finishes

NADCAP & NABL approved partners

Laser, CMM & hand inspections

Hardware installation & assembly

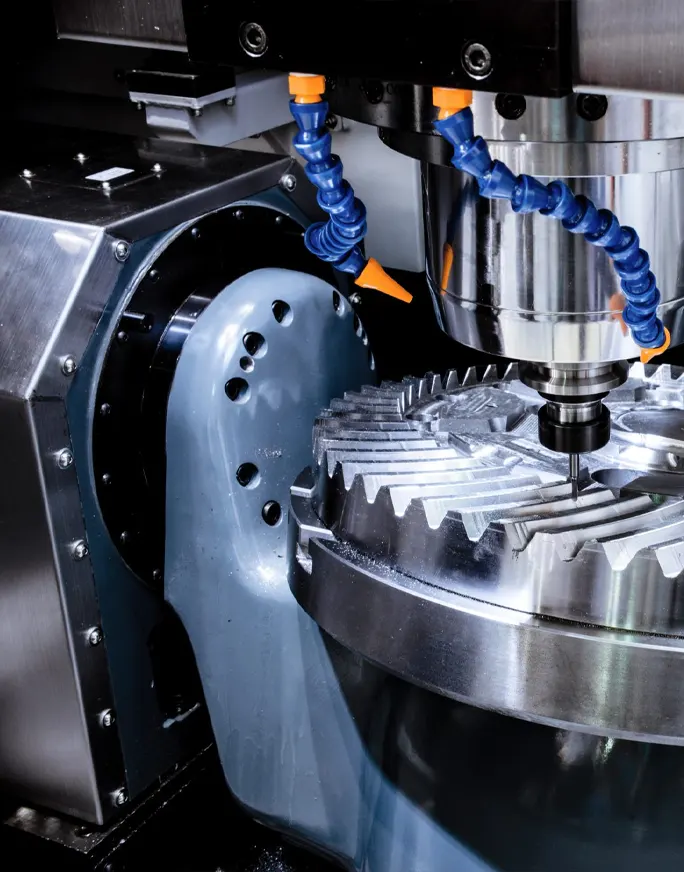

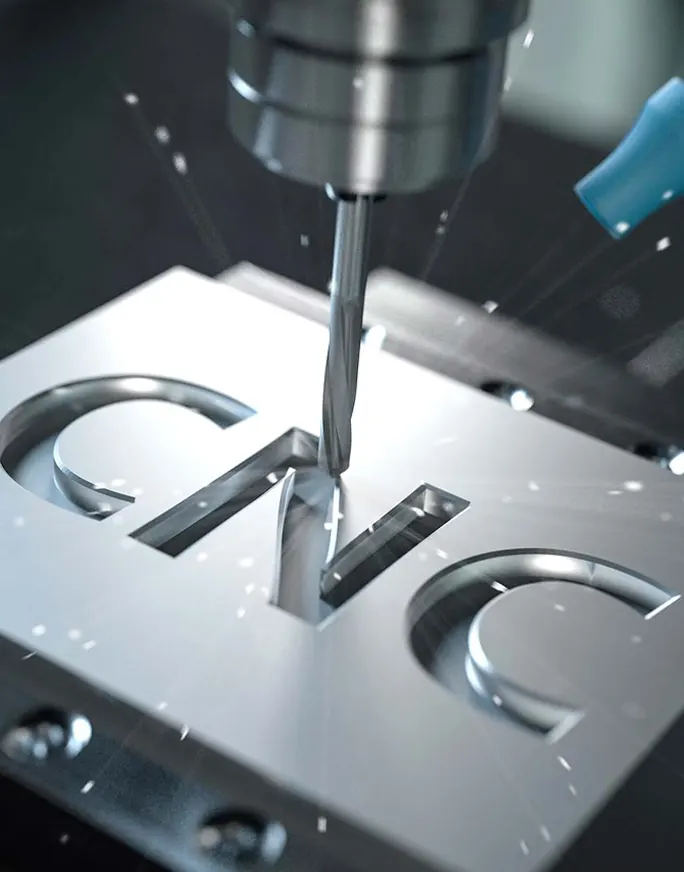

Advanced 3, 4, and 5-axis CNC machining capabilities to accurately produce both simple components and highly complex geometries with precision.

| Metals, PEEK, And ULTEM with Drawing | Other Plastics with Drawing | No Drawing | |

|---|---|---|---|

| Linear Dimension | +/- 0.0025 mm +/- 0.0001 inch | +/- 0.05 mm +/- 0.002 inch | ISO 2768 Medium |

| Hole Diameters (Not Reamed) | +/- 0.0025 mm +/- 0.0001 inch | +/- 0.05 mm +/- 0.002 inch | ISO 2768 Medium |

| Shaft Diameters | +/- 0.0025 mm +/- 0.0001 inch | +/- 0.05 mm +/- 0.002 inch | ISO 2768 Medium |

Finish Options: Available as-machined, media blasted, or hand-polished

Mill Lead Time: As fast as 7 days

Finish Options: Media blasting, Tumbling

Mill Lead Time: As fast as 3 days

We offer part lengths of up to 48 inches, depending on the specific manufacturing process used. If your project requires dimensions beyond this range, feel free to reach out to discuss custom options. The tolerances listed represent minimums achievable under ideal conditions; actual tolerances may vary depending on the chosen material, machining process, or complexity of the part geometry.

As your one-stop manufacturing partner, Sunrise Industries maintains a complete inventory of ready-to-sell raw materials alongside custom parts fabrication and full engineering services. From prototyping to production, we provide everything at a single location—serving all industrial sectors and transforming manufacturing value chains.