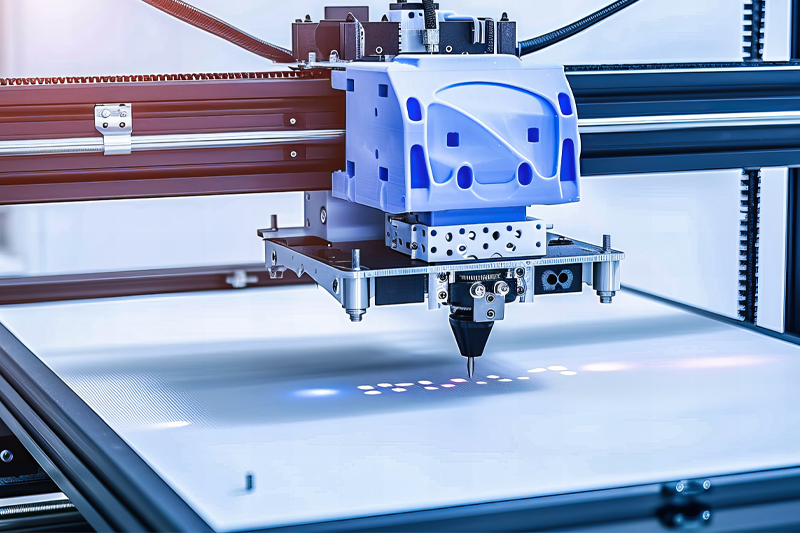

An online custom laser cutting service is available for a wide range of materials, including metal, plastic, rubber, foam, and wood. This service provides a cost-effective, on-demand solution for various manufacturing needs. It supports everything from prototypes to low-volume batches and high-volume production runs, making it ideal for projects of any scale. Whether you need precision parts in acrylic, sheet metal, or soft materials, laser cutting ensures quality, speed, and flexibility.

You can instantly receive a quote by uploading a 3D CAD file in formats such as STEP, STP, SLDPRT, DXF, IPT, PRT, or SAT using the Instant Quoting Engine. The pricing is transparent—what you see is what you pay. Prototype pricing includes tariffs and standard parcel shipping, with no hidden fees.