Rene 41® is a precipitation-hardening, nickel-based alloy known for its exceptional high-temperature strength and oxidation resistance. These sheets and plates are designed for use in highly stressed environments, particularly where elevated temperatures are a concern. The alloy is commonly used in aerospace, defense, and industrial applications due to its consistent mechanical performance.

Rene 41® plates offer outstanding mechanical properties, including extreme toughness, high tensile strength, and excellent resistance to heat and oxidation. The alloy maintains predictable shrinkage during heat treatment and can withstand intense thermal and mechanical stress. These properties make it ideal for components like turbine blades, springs, and missile parts.

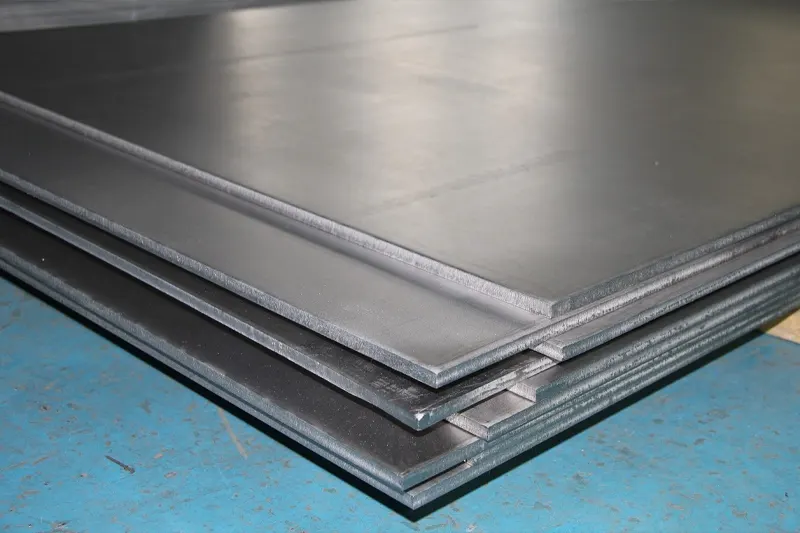

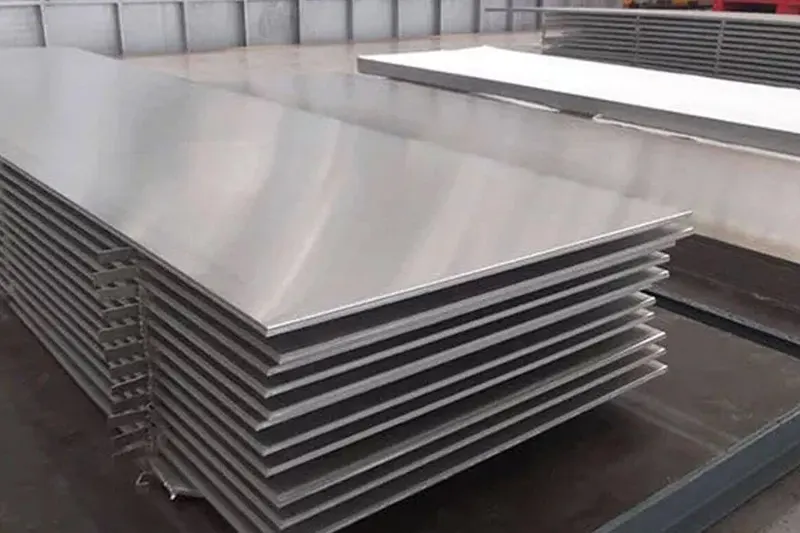

The alloy is available in various forms, including hot rolled sheets, cold rolled sheets, chequered plates, and perforated sheets. During production, Rene 41® is subjected to rigorous processing standards, including solution treatment and aging. Lower solution temperatures contribute to increased tensile strength, while proper heat treatment ensures uniform mechanical behavior.

Rene 41® alloy sheets and plates are typically welded using the inert-gas-arc method. To prevent issues such as strain age cracking, it’s crucial that the material is in a fully solution-treated condition before welding. Strict quality control measures, including both destructive and non-destructive testing, are implemented to ensure product reliability.

Each stage of the production process is carefully monitored by trained professionals using advanced technologies. Products are tailored to customer specifications and delivered safely and on time. Services also include flexible customization, packaging, and efficient logistics to ensure maximum customer satisfaction.

AMS 5545

AMS, AMS, API

3mm-80mm

0.5 MM TO 200 MM THICK IN 1000 MM TO 2500 MM WIDTH & 2500 MM TO 12500 MM LENGTH

RENE 41 UNS-N-07041/N-08041

| STANDARD | Material No | UNS |

|---|---|---|

| RENE 41 | 2.4973 | N07041 / N08041 |

| Grade | Al | B | C | Co | Cr | Cu | Fe | Mn | Mo | Ni | S | Si |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RENE 41 | 1.40-1.60 | 0.0030-0.0100 | 0.12 min | 10.00-12.00 | 18.00-20.00 | 0.50 min | 5.0 min | 0.10 min | 9.0-10.50 min | Remainder | 0.0150 min | 0.5000 min |

| Grade | Rp0.2 (MPa) | Rm (MPa) | AKV (J) | A (%) | Z (%) | Hardness |

|---|---|---|---|---|---|---|

| RENE 41 | 572 (≥) | 169 (≥) | 14 | 13 | 23 | HBW 342 |

RENE 41 Sheets & Plates are premium, nickel-based superalloys designed to maintain high strength and stability in extreme heat and stress conditions. Known for their excellent oxidation resistance, these sheets are ideal for aerospace, turbine, and missile applications. With outstanding mechanical properties and corrosion resistance, RENE 41 materials deliver reliable performance in demanding environments.

Sunrise Industries supplies top-quality RENE 41 Sheets & Plates in various sizes and finishes to meet the precise needs of critical industries. These products are manufactured with strict quality standards and are available for both custom and bulk orders. With proven performance and durability, RENE 41 is a trusted choice for applications where strength at high temperatures is essential.

As your one-stop manufacturing partner, Sunrise Industries maintains a complete inventory of ready-to-sell raw materials alongside custom parts fabrication and full engineering services. From prototyping to production, we provide everything at a single location—serving all industrial sectors and transforming manufacturing value chains.