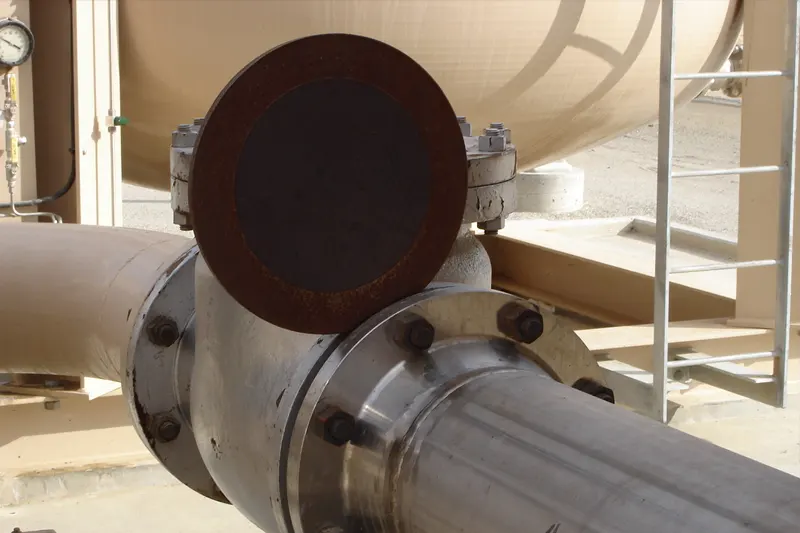

A wide range of Spectacle Blind Flanges is manufactured and exported in accordance with global standards such as ANSI B16.5, ANSI B16.47, MSS SP-44, DIN-2527, and BS-4504. These include flanges made from Stainless Steel, Carbon Steel, Duplex & Super Duplex Steel, Alloy Steel, Inconel, Monel, Hastelloy, Titanium, Alloy 20, Copper Nickel, and Nickel Alloys.

Available in various pressure classes such as 150 LBS, 300 LBS, 600 LBS, and beyond, these flanges are designed for use in critical isolation applications across industries like oil & gas, chemical processing, marine, power plants, and more.

Inventory includes products ready for delivery to regions such as Saudi Arabia, Qatar, Malaysia, UAE, and the United States, offering reliable solutions tailored to international specifications and unique project needs.