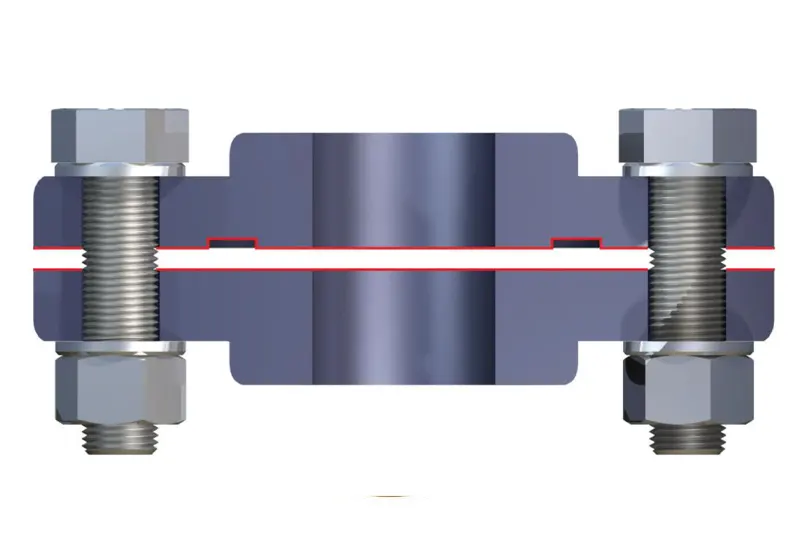

Lap Joint Flanges are widely used in piping systems for easy installation and maintenance. These flanges are ideal for applications where frequent dismantling is required, as they can be assembled without welding. They are suitable for both low and high-pressure services, particularly in environments that require corrosion resistance and strength. Lap Joint Flanges are compatible with various pipe materials and are often used with alloy steel for applications demanding superior durability and reliability.

These flanges are manufactured in compliance with international standards such as ASME B16.5 and ASME B16.47, ensuring high quality and precision. They are available in a wide range of materials including stainless steel, carbon steel, duplex steel, super duplex steel, and high nickel alloys like Monel, Inconel, and Hastelloy. Each material offers unique advantages in terms of mechanical strength, corrosion resistance, and temperature tolerance, making Lap Joint Flanges suitable for diverse industrial requirements.

One of the key benefits of Lap Joint Flanges is their ability to be easily aligned and adjusted, which makes them especially useful in systems where precise orientation is necessary. They are often paired with stub ends, allowing for smooth surface contact and reducing wear on the flange itself. These flanges are also preferred for systems operating at or near atmospheric pressure, as well as for high-pressure applications that demand reliable sealing performance without the risk of leakage under cyclic conditions or bending stresses.

Lap Joint Flanges are supplied in custom sizes and dimensions to meet the specific needs of various industries, including oil and gas, petrochemical, power generation, marine, and chemical processing. They are also exported to multiple international markets such as Qatar, Saudi Arabia, Bahrain, Singapore, Malaysia, Turkey, the United States, and Europe. Their versatility and adaptability to different environments make them a popular choice for global industrial projects.

Manufacturers and suppliers of Lap Joint Flanges also offer a variety of specialized types, such as BS-4504 Lap Joint Flanges, Alloy Steel Lap Joint Flanges, Copper Nickel Lap Joint Flanges, and Inconel 600 Lap Joint Flanges. These products undergo strict quality control and testing to ensure durability and compliance with industry standards. With options available in both standard and customized specifications, Lap Joint Flanges provide a reliable solution for connecting pipelines in demanding operational conditions.

Lap Joint Flanges

ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H,904L

ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91

ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020).

UNS No. C 10100, 10200, 10300, 10800, 12000, 12200, 70600, 71500, UNS No. C 70600 (Cu -Ni- 90/10), C 71500 (Cu -Ni- 70/30)

Lap Joint Flanges are available in a wide size range, starting from 1/2″ (15 NB) up to 48″ (1200 NB), making them suitable for small to large-scale piping applications. They are designed and manufactured according to various international standards, ensuring compatibility and reliability in diverse industrial environments.

These flanges adhere to ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, and AWWA standards, and can also be produced as per custom drawings based on specific project requirements. They are offered in multiple pressure classes, including 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, and 2500 LBS, as well as DIN standard ND-6, 10, 16, 25, and 40, covering a wide range of pressure ratings.

For flange face types, Raised Face (RF) and Ring Type Joint (RTJ) options are available, providing secure sealing and leak-proof performance in critical applications. They also comply with British Standards like BS4504, BS1560, and BS10, ensuring global adaptability and high-quality performance.

Lap Joint Flanges are manufactured in sizes ranging from 1/2″ (15 NB) to 48″ (1200 NB), meeting the needs of various piping systems. They are designed as per ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, and AWWA standards, along with BS4504, BS1560, BS10, and multiple DIN specifications such as DIN2527, DIN2566, DIN2573, and more. These flanges are available in different pressure classes like 150, 300, 600, 900, 1500, and 2500 LBS, as well as DIN ND-6, 10, 16, 25, and 40 ratings, ensuring versatility for various applications.

They are offered with Raised Face (RF) and Ring Type Joint (RTJ) face types for secure sealing and leak-proof performance. Built to meet stringent quality norms, these flanges conform to NACE MR0175/ISO 15156, making them suitable for sour service environments in oil, gas, and petrochemical industries. With such diverse specifications and compliance, Lap Joint Flanges ensure reliability, durability, and compatibility with global industrial standards.

As your one-stop manufacturing partner, Sunrise Industries maintains a complete inventory of ready-to-sell raw materials alongside custom parts fabrication and full engineering services. From prototyping to production, we provide everything at a single location—serving all industrial sectors and transforming manufacturing value chains.