Forged Socket Weld and Threaded Elbows are essential fittings used to connect two sections of pipe or tube, allowing a change in the flow direction. These elbows are commonly available in three main types – 180-degree elbows, 90-degree elbows, and 45-degree elbows – making them versatile for different piping layouts. They are widely used in high-pressure applications where a strong and leak-proof joint is required, ensuring reliability in demanding industrial environments.

These elbows are manufactured in various materials, including stainless steel, carbon steel, duplex and super duplex steel, alloy steel, copper nickel, Inconel, Hastelloy, and other high nickel alloys. They comply with international standards such as ASTM A182 and ASME B16.11, ensuring precision, strength, and durability. Their robust design makes them suitable for industries such as oil and gas, petrochemicals, power generation, chemical processing, and marine engineering.

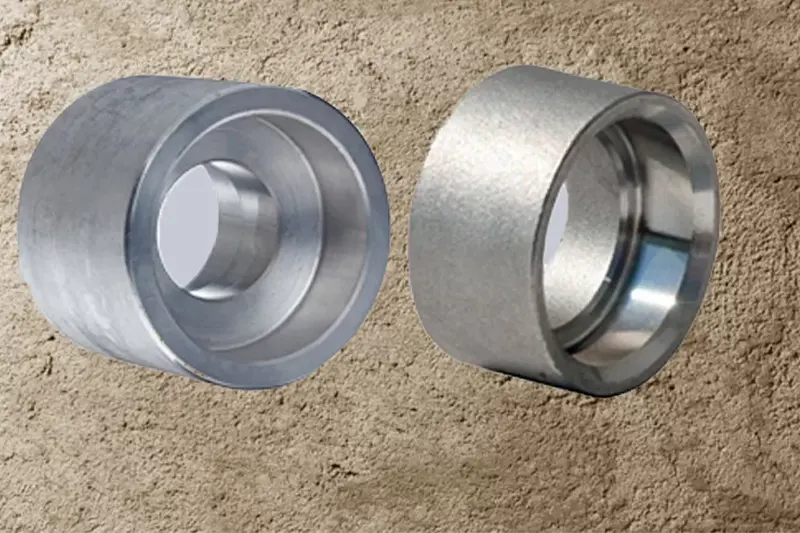

Socket weld elbows are specifically designed for applications where high integrity and leak-proof performance are critical. They are ideal for smaller pipe sizes in high-pressure systems and are available in various sizes, pressure ratings, and customized specifications to suit different operational needs. Threaded elbows, on the other hand, are preferred for systems that require easy assembly and disassembly without welding.

These fittings are offered in customized sizes, shapes, and dimensions to meet the specific requirements of different projects. They are widely exported to Qatar, Bahrain, Saudi Arabia, Indonesia, the United States, Singapore, Malaysia, Turkey, UAE, Russia, Ukraine, South Africa, and Australia, reflecting their global demand and quality standards.

Specialized types include MSS SP-79 Forged Elbows, Duplex Steel Elbows, Super Duplex Socket Weld Elbows, and Alloy Steel Threaded Forged Elbows, each designed for unique operational environments. With excellent resistance to pressure, corrosion, and wear, forged elbows provide long-lasting performance, making them a trusted choice for critical piping systems.

Socket Weld Elbow

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F904L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR.A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C

ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200), UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400), UNS 8020 (ALLOY 20 / 20 CB3), UNS 8825 (INCONEL 825), UNS 6600 (INCONEL 600), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276).

ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 (CU -NI- 90/10), C 71500 (CU -NI- 70/30)

Socket Weld Elbows are available in a size range from 1/4″ NB to 4″ NB, making them ideal for small-bore, high-pressure piping systems. They are designed to meet the requirements of various industries and are manufactured using high-quality materials for durability and reliability.

These elbows are produced in accordance with ASTM A182 and ASTM SA182 standards, ensuring superior mechanical strength and corrosion resistance. They also follow dimensional standards like ASME B16.11, MSS SP-79, MSS SP-95, MSS SP-83, MSS SP-97, and BS 3799, maintaining precision and compatibility with different piping systems.

Socket Weld Elbows are offered in multiple pressure classes such as 2000 LBS, 3000 LBS, 6000 LBS, and 9000 LBS, making them suitable for various high-pressure applications. They are available in different connection types including Socket Weld fittings and Screwed-Threaded fittings with NPT, BSP, and BSPT threads, providing flexibility in installation.

In terms of design, they are supplied in various forms such as 45-degree elbows, 90-degree elbows, forged elbows, threaded elbows, and socket weld elbows, catering to a wide range of piping layout requirements. Moreover, these forged elbows conform to NACE MR0175/ISO 15156, making them suitable for sour service environments in oil, gas, and petrochemical industries.

Socket Weld Elbows are available in a size range from 1/4″ NB to 4″ NB, making them ideal for small-bore, high-pressure piping systems. They are manufactured as per ASTM A182 and ASTM SA182 standards, with dimensions following ASME B16.11, MSS SP-79, MSS SP-83, MSS SP-95, MSS SP-97, and BS 3799. These elbows are designed for various pressure classes like 2000 LBS, 3000 LBS, 6000 LBS, and 9000 LBS, ensuring reliable performance in critical applications.

Available in multiple forms such as 45-degree elbows, 90-degree elbows, forged elbows, threaded elbows, and socket weld elbows, they suit different piping layouts. Connection options include Socket Weld and Screwed-Threaded fittings in NPT, BSP, and BSPT threads. Additionally, these forged elbows conform to NACE MR0175/ISO 15156, making them suitable for sour service and demanding industrial environments.

As your one-stop manufacturing partner, Sunrise Industries maintains a complete inventory of ready-to-sell raw materials alongside custom parts fabrication and full engineering services. From prototyping to production, we provide everything at a single location—serving all industrial sectors and transforming manufacturing value chains.