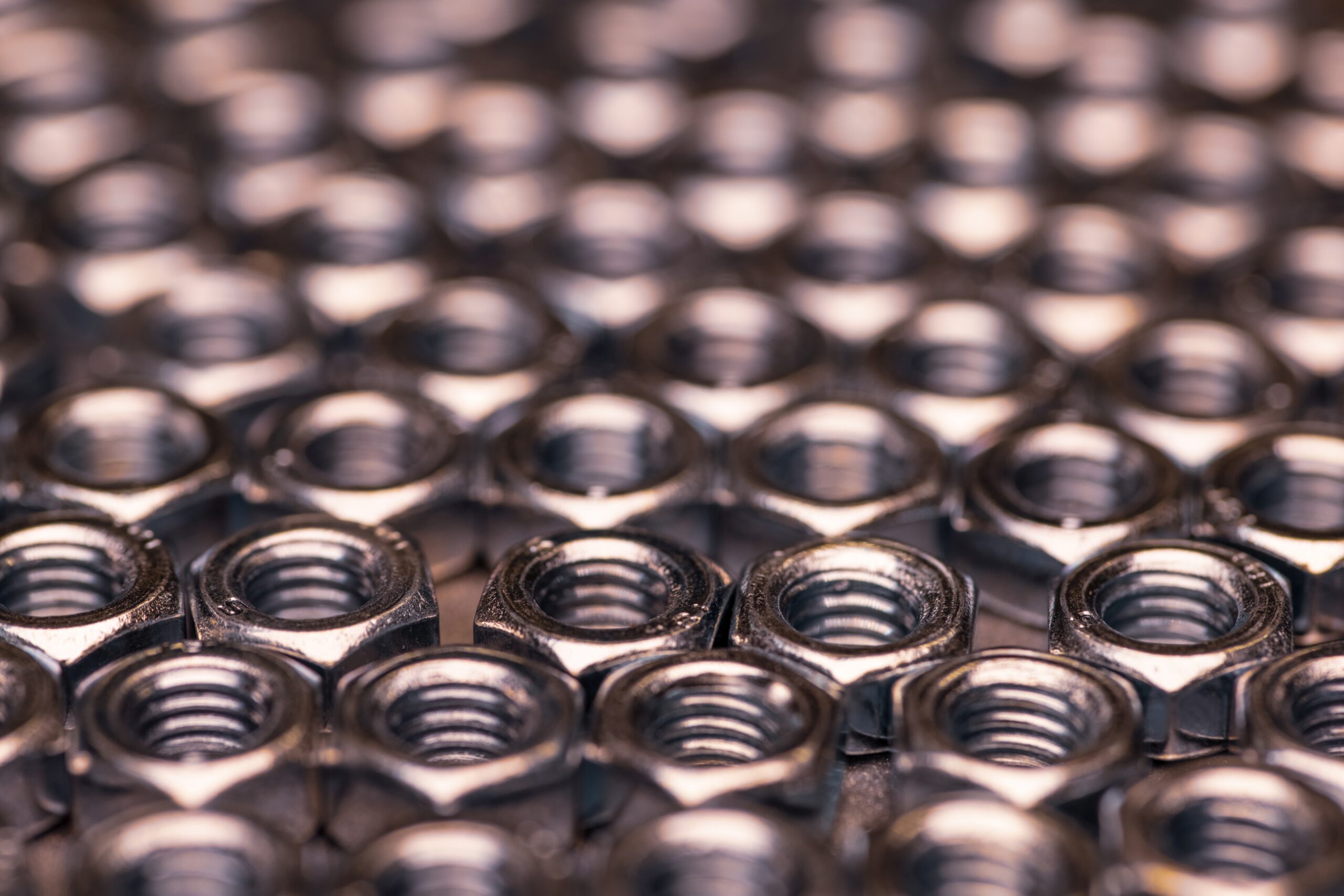

Nuts are essential fasteners designed with a threaded hole that pairs with a corresponding bolt to securely join multiple components together. They are commonly used in machinery, construction, automotive, and industrial equipment. In applications where vibration or rotation could loosen a nut, various locking mechanisms are employed, such as lock wires, safety pins, nylon inserts, adhesives, or oval-shaped threads. This ensures a stable and long-lasting connection even under challenging operating conditions.

These nuts are manufactured in a wide variety of materials including stainless steel, carbon steel, alloy steel, duplex and super duplex steel, copper-nickel alloys, Monel, Inconel, Hastelloy, and other high-performance materials. The choice of material ensures durability, excellent mechanical strength, and resistance to corrosion, making them suitable for both indoor and outdoor industrial environments. Precision engineering and adherence to international standards guarantee reliability and interchangeability.

A broad selection of nut types is available to suit diverse fastening needs. These include sleeve nuts, wing nuts, heavy hex nuts, serrated flange nuts, cap nuts, dome nuts, coupling nuts, square nuts, thin nuts, 2-way lock nuts, ACME nuts, and T-tee nuts. Each type serves a specific purpose, from general assembly to specialized applications where locking, spacing, or decorative finishes are required.

Customization options are also offered to meet specific project requirements, with nuts available in various sizes, thread types, coatings, and finishes. High-tensile and precision-threaded nuts are widely used in industries such as oil and gas, petrochemical, marine, construction, transportation, and infrastructure projects. Special surface treatments like zinc plating, galvanizing, or PTFE coating can be applied for enhanced durability and corrosion resistance.

These high-quality nuts are trusted and widely supplied to global markets including Qatar, Bahrain, Saudi Arabia, Kuwait, Indonesia, Singapore, Malaysia, Turkey, UAE, Russia, Ukraine, South Africa, Australia, and the United States. Their robust design, material versatility, and reliable performance have made them a preferred choice for engineers, contractors, and industrial users worldwide.

Nuts

AISI 302, 304, 304L,316, 316L, 310, 317, 317L, 321, 347, 410, 420,904L etc.

ASTM / ASME A815 UNS No. S31803, UNS No. S32205, UNS No. S31254, UNS No. S31550, UNS No. S32750, UNS No. S32760

ASTM A307, A193

ASTM / ASME A/SA 193 / 194 B 6, B 7/ B 7M, B 16, 2, 2HM, 2H, GR 6, B 7, B 7M

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200), UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400), UNS 8020 (ALLOY 20 / 20 CB3), UNS 8825 (INCONEL 825), UNS 6600 (INCONEL 600), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276).

Nuts are manufactured in compliance with DIN, ASTM, BS, and other international standards, ensuring precision, durability, and global compatibility. They are available in a wide size range from M3 to M56 (3/6″ to 4″), with custom sizes available to meet specific project requirements. The length of these nuts typically ranges from 3 mm to 200 mm, making them suitable for both light-duty and heavy-duty fastening applications.

A variety of nut types are offered to suit different industrial needs, including square nuts, hexagon thin nuts, hexagon nuts, standard hex nuts, hex coupling nuts, and hex domed cap nuts. Each type is designed for specific applications, ensuring secure and reliable fastening solutions for construction, machinery, automotive, and industrial projects.

Nuts are produced according to DIN, ASTM, BS, and other international standards, ensuring excellent quality, durability, and precision for various industrial applications. They come in a size range from M3 to M56 (3/6″ to 4″) with customized dimensions available as per project needs. The length typically varies from 3 mm to 200 mm, making them suitable for both small-scale assemblies and heavy-duty installations.

A wide variety of nut types are available to meet different fastening requirements, including square nuts, hexagon thin nuts, standard hex nuts, hex coupling nuts, and hex domed cap nuts. Each nut is designed for specific uses, providing secure and reliable fastening solutions for construction, machinery, automotive, petrochemical, and other industrial sectors.

As your one-stop manufacturing partner, Sunrise Industries maintains a complete inventory of ready-to-sell raw materials alongside custom parts fabrication and full engineering services. From prototyping to production, we provide everything at a single location—serving all industrial sectors and transforming manufacturing value chains.