Heavy Duty Eye & Eye Swivels are essential components used in marine, industrial, and construction sectors for lifting and rigging applications. These swivels are designed to prevent line twisting under load and are highly efficient in maintaining the stability and direction of cables or ropes during operation. Their robust construction ensures reliability even in extreme conditions.

These swivels are available in a wide range of materials such as Stainless Steel 304, 304L, 316, 316L, Carbon Steel, Alloy Steel, and Super Duplex Steel. Exported and supplied across regions including Oman, Bahrain, Qatar, Kuwait, Saudi Arabia, Nigeria, UAE, and Muscat, they are widely trusted by industries for their strength and corrosion resistance. Their popularity spans across Asia-Pacific, Africa, and the Middle East.

Heavy Duty Eye & Eye Swivels are manufactured in accordance with international quality standards and often feature CE and SWL (Safe Working Load) markings. They are tested for load-bearing capacity and durability, making them suitable for high-stress environments. These swivels can withstand heavy loads and are precision engineered for optimal performance.

These swivels are designed for easy integration with various setups and can be connected using rivet snaps, punches, or stud fittings. They are commonly used in leather, fabric, and metal assemblies where flexible movement is required without tangling or twisting of connected parts. Their design ensures smooth rotation under tension and repeated use.

The swivels are typically available in sizes ranging from 1/4″ to 1/2″, and are precision cast for enhanced strength and corrosion resistance. Stainless steel versions offer maximum protection in marine environments, while forged carbon steel options are preferred for heavy industrial loads. Their heavy-duty nature makes them a reliable choice for both static and dynamic load applications.

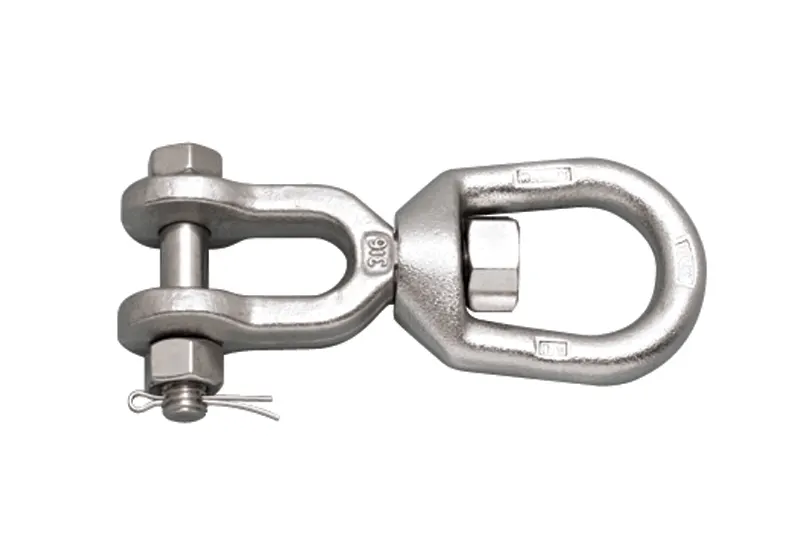

Heavy Duty Eye & Eye Swivel

| ITEM | A (size) | B | C | D | WLL (LB) | WT (LB) |

|---|---|---|---|---|---|---|

| ISCO-HDEES01 | 1/4" | 0.58" | 1.00" | 3.50" | 750 | 0.27 |

| ISCO-HDEES02 | 5/16" | 0.74" | 1.25" | 4.40" | 1,400 | 0.52 |

| ISCO-HDEES03 | 3/8" | 0.88" | 1.50" | 5.26" | 2,000 | 0.88 |

| ISCO-HDEES04 | 1/2" | 1.10" | 2.00" | 7.00" | 3,300 | 2.00 |

1/ 4” to 1/ 2” & As Per Drawings.

As per Standard Length & As per Clients Requirements.

Electro Polished (EP), Aluminium Finish, Black Carbon Coated, Galvanised Coating, Bright Etc…

Heavy Duty Eye & Eye Swivel Manufacturer Name, Heavy Duty Eye & Eye Swivel Size, Heavy Duty Eye & Eye Swivel Grades, Heavy Duty Eye & Eye Swivel Weight Load Capacity Etc.

Jaw & Jaw Swivel, Fed. Spec. Eye & Eye Swivel, Fed. Spec. Jaw & Eye Swivel, Fed. Spec. Chain Swivel, Forged Jaw & Jaw Swivel, Eye & Eye Swivel, Heavy Duty Eye & Eye Swivel, Eye & Jaw Swivel, Eye & Jaw Swivel w/ No Snag Pin, Heavy Duty Eye & Jaw Swivel, Heavy Duty Jaw & Jaw Swivel Etc…

| Stainless Steel Heavy Duty Eye & Eye Swivel: | Mild Steel (MS) Heavy Duty Eye & Eye Swivel: |

|---|---|

|

|

The Heavy Duty Eye & Eye Swivel is a crucial rigging accessory designed to connect two components while allowing them to rotate independently. Its primary function is to prevent rope, wire, or chain from twisting under load, which helps reduce stress and prolong the life of connected equipment. These swivels are widely used in marine, construction, and lifting operations due to their high load-bearing capacity and secure locking mechanism.

Heavy Duty Eye & Eye Swivels are manufactured in a variety of materials such as Stainless Steel 304, 316, Carbon Steel, and Mild Steel, catering to different environments and applications. For example, stainless steel variants are preferred in marine and corrosive environments due to their resistance to rust, while carbon steel is suitable for heavy-duty industrial tasks. Their wide range of sizes and strengths makes them adaptable for both light and extreme load conditions.

As your one-stop manufacturing partner, Sunrise Industries maintains a complete inventory of ready-to-sell raw materials alongside custom parts fabrication and full engineering services. From prototyping to production, we provide everything at a single location—serving all industrial sectors and transforming manufacturing value chains.