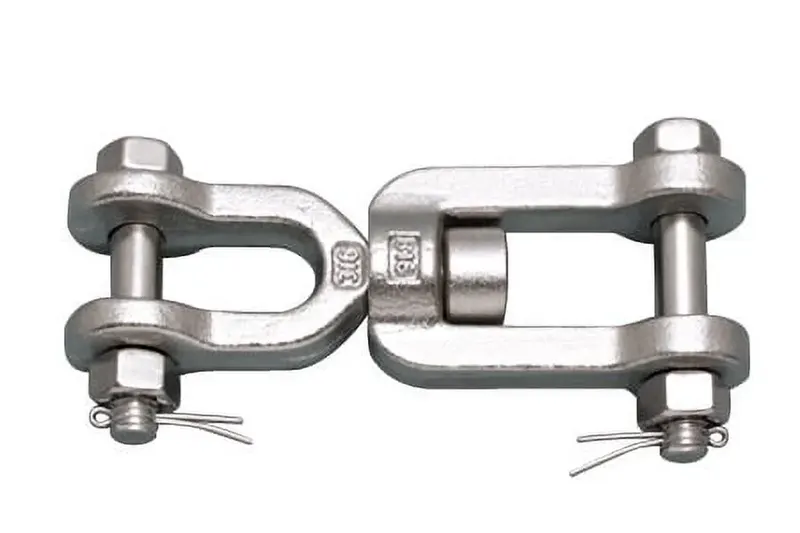

Fed. Spec. Chain Swivels are critical components in various rigging and lifting operations where chain twisting and tangling must be avoided. These swivels are engineered to offer optimal performance in environments demanding strength, durability, and freedom of movement. Commonly used in marine, industrial, and offshore applications, they help maintain chain alignment under load without compromising safety.

These swivels are manufactured from premium-grade materials such as Stainless Steel 316, 316L, 304L, Alloy Steel, Carbon Steel, and Super Duplex Steel. The high-quality metals ensure excellent corrosion resistance and extended service life, even in highly corrosive environments such as saltwater or chemical processing plants. Their robust design supports load capacities up to 5,140 lbs, making them suitable for heavy-duty applications.

Fed. Spec. Chain Swivels are produced according to stringent standards and are marked with Safe Working Load (SWL) to ensure operator awareness during use. They are available in a wide range of sizes, typically from 3/16″ to 5/8″, and are designed with an extra-large eye opening to accommodate oversized chains and cables. Their precision forging ensures high tensile strength and reliability under load.

These swivels function primarily as positioning devices and are not intended to swivel while bearing weight. Their main advantage lies in reducing stress from torque and preventing kinks or knots in chains or ropes during lifting, hauling, or anchoring operations. The design provides an efficient and safe means of handling rotating or shifting loads without causing wear or deformation to the connected chains.

Manufactured in accordance with Federal Specification RR-C-271F Type VII, Class 1 (excluding stainless steel 316 in some cases), these components meet rigorous performance and safety benchmarks. Their compliance with recognized standards ensures consistent quality across applications in shipping, construction, oil & gas, and industrial maintenance.

Fed. Spec. Chain Swivel

| ITEM | A (size) | B | C | D | E | F | WLL (LB) | WT (LB) |

|---|---|---|---|---|---|---|---|---|

| ISCO-FSCS01 | 3/16" | 0.25" | 0.75" | 0.84" | 0.50" | 2.28" | 700 | 0.13 |

| ISCO-FSCS02 | 1/4" | 0.31" | 0.75" | 0.80" | 0.63" | 2.56" | 900 | 0.17 |

| ISCO-FSCS03 | 5/16" | 0.38" | 1.25" | 1.17" | 0.75" | 3.37" | 1,200 | 0.43 |

| ISCO-FSCS04 | 3/8" | 0.50" | 1.25" | 1.06" | 1.00" | 3.74" | 3,400 | 0.56 |

| ISCO-FSCS05 | 1/2" | 0.63" | 1.50" | 1.45" | 1.25" | 4.68" | 4,400 | 1.15 |

| ISCO-FSCS06 | 5/8" | 0.75" | 1.75" | 1.73" | 1.50" | 5.71" | 6,000 | 2.02 |

3/16” to 5/8” & As Per Drawings.

As per Standard Length & As per Clients Requirements.

Electro Polished (EP), Aluminium Finish, Black Carbon Coated, Galvanised Coating, Bright Etc…

Fed. Spec. Chain Swivel Manufacturer Name, Fed. Spec. Chain Swivel Size, Fed. Spec. Chain Swivel Grades, Fed. Spec. Chain Swivel Weight Load Capacity Etc.

Jaw & Jaw Swivel, Fed. Spec. Eye & Eye Swivel, Fed. Spec. Jaw & Eye Swivel, Fed. Spec. Chain Swivel, Forged Jaw & Jaw Swivel, Eye & Eye Swivel, Heavy Duty Eye & Eye Swivel, Eye & Jaw Swivel, Eye & Jaw Swivel w/ No Snag Pin, Heavy Duty Eye & Jaw Swivel, Heavy Duty Jaw & Jaw Swivel Etc…

Stainless Steel Fed. Spec. Chain Swivel:

|

Mild Steel (MS) Fed. Spec. Chain Swivel:

|

Fed. Spec. Chain Swivels are designed to connect chain links while preventing twisting and tangling during use. These swivels are ideal for lifting, rigging, and marine applications where rotation must be minimized under load. Their construction helps ensure long-lasting performance, even under extreme stress or harsh environments.

Manufactured according to RR-C-271F Type VII, Class 1 standards, these chain swivels provide exceptional durability and safety. Available in sizes ranging from 3/16″ to 5/8″, they are commonly made from stainless steel 316 or other robust alloys, offering excellent corrosion resistance and a Safe Working Load (SWL) of up to 5,140 lbs.

As your one-stop manufacturing partner, Sunrise Industries maintains a complete inventory of ready-to-sell raw materials alongside custom parts fabrication and full engineering services. From prototyping to production, we provide everything at a single location—serving all industrial sectors and transforming manufacturing value chains.