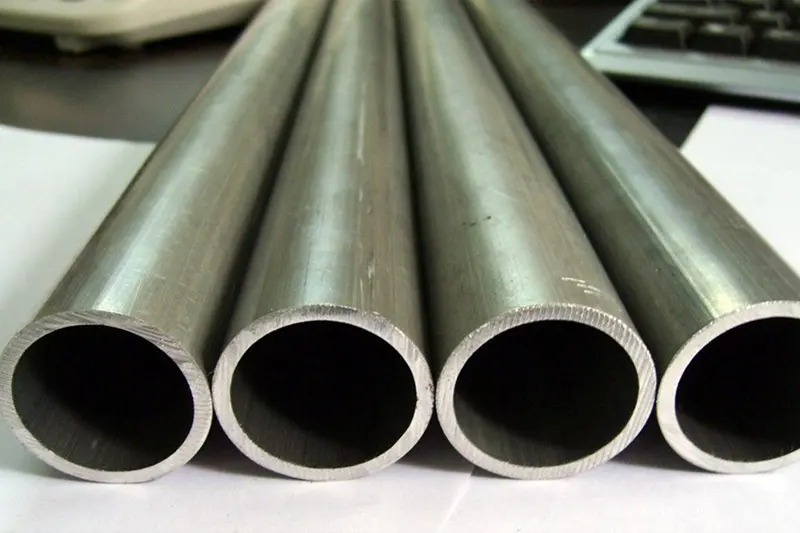

Sunrise Industries manufactures Cu-Ni 90/10 EFW Pipes and Rectangular Tubes for specialized piping applications in marine, shipbuilding, and industrial plants. These tubes have excellent corrosion resistance in high-velocity seawater conditions due to added manganese and iron. Rectangular tubes are often used in structural applications, seawater piping, and auxiliary systems. The pipes and tubes are available in multiple lengths, wall thicknesses, and custom dimensions. Their strength and reliability make them suitable for offshore platforms, desalination plants, and chemical processing plants.

ASTM B111 Cupro Nickel 90/10 Pipe & Tubes Specification

Grades : Cu-Ni 90/10 (C70600)

Standards: ASTM, ASME and API

Specifications: ASTM / ASME SB 111 / 151 / 466

Size: 1/8″ TO 6” IN OD & NB IN 1/8” to 48”

Length: 3mm to 6000mm

Wall Thickness: 0.15mm and 8mm / Sch.5 to Sch. 160 & Sch. STD, Sch. XS, Sch. XXS

Type: Seamless / ERW / Welded / Fabricated / LSAW Pipes

Form: Round, Square, Rectangular, Hydraulic Etc.

Our Cupro Nickel C70600 Pipe & Tubes conforms to NACE MR0175/ISO 15156.

| Standard | WERKSTOFF NR. | UNS | MIL | SAE | JIS | BS | EN |

|---|---|---|---|---|---|---|---|

| Cu-Ni 90/10 | 2.0872 | C70600 | C-15726 | J461, J463 | - | CN-10-2 | CW-35-2H |

| Grade | Cu | Ni | Pb | Mn | Fe | Zn | P | S | N |

|---|---|---|---|---|---|---|---|---|---|

| Cu-Ni 90/10 | 88.6 Min. | 9.0 - 11.0 | 0.05 max | 1.0 max | 1.8 max | 1.0 max | - | - | - |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2% offset) | Elongation |

|---|---|---|---|---|

| 0.323 lb/in³ at 68 °F | 2100 °F | 50,000 psi – 38 ksi | 20,000 psi – 15 ksi | 30 % |

Sunrise Industries specializes in custom Cu-Ni 90/10 Pipes & Tubes for marine, offshore, and industrial applications. Available in seamless, welded, ERW, EFW, and rectangular forms, these tubes can be tailored to specific project needs. Ideal for desalination plants, offshore oil and gas facilities, shipbuilding, and power generation, the products provide excellent corrosion resistance, high tensile strength, and long service life. Customers can select dimensions, wall thicknesses, and lengths according to their requirements, ensuring reliable performance and easy integration into demanding systems worldwide.

| Cu-Ni 90/10 Precision Tubes Dealer in Africa | Cu-Ni 90/10 Square Pipes Exporter in South Africa |

| Copper Nickel 90/10 Seamless Pipes Supplier | C70600 Cu-Ni Square Tubes Dealer in Egypt |

| Cupro Nickel UNS C70600 Seamless Tubes in Tanzania | Cu-Ni 90/10 Hollow Pipes Supplier in Ghana |

| Copper Nickel 90/10 Welded Pipes Dealer in Peru | Cu-Ni 90/10 Hollow Tubes Supplier |

| Cu-Ni 90/10 Welded Tubes Exporter in Madagascar | ASTM B466 Cu-Ni 90/10 EFW Pipes |

| Cu-Ni 90/10 Round Pipes Stockiest in Libya | Copper Nickel 90/10 EFW Tubes in Zambia |

| Cu-Ni 90/10 ERW Pipes Manufacturer in India | ASTM B466 Cu-Ni Capillary Tubes in Ethiopia |

| 90/10 Copper Nickel ERW Tubes Stockholder | Cu-Ni 90/10 Capillary Tubes in Brazil |

| Cu-Ni C70600 Rectangular Pipes in Nigeria | Cu-Ni 90/10 Welded Pipes Manufacturer in India |

| ASME SB111 Cu-Ni 90/10 Pipes/Tubes in Chile | 90/10 Cupro Nickel Rectangular Tubes in Algeria |

| Cu-Ni 90/10 B111 Rectangle Pipe in Kuwait | Cu-Ni 90/10 B111 Rectangle Pipe in Bahrain |

As your one-stop manufacturing partner, Sunrise Industries maintains a complete inventory of ready-to-sell raw materials alongside custom parts fabrication and full engineering services. From prototyping to production, we provide everything at a single location—serving all industrial sectors and transforming manufacturing value chains.