Our SS Decorative Omega Profiles are manufactured using advanced CNC bending technology. Before bending, sheets are accurately cut to the required sizes with high-precision laser cutting machines. To enhance aesthetics and achieve a sharp 90° bend, V-grooving is performed on the sheets prior to bending. These profiles are available in both standard and custom sizes, designed to meet diverse interior and architectural requirements.

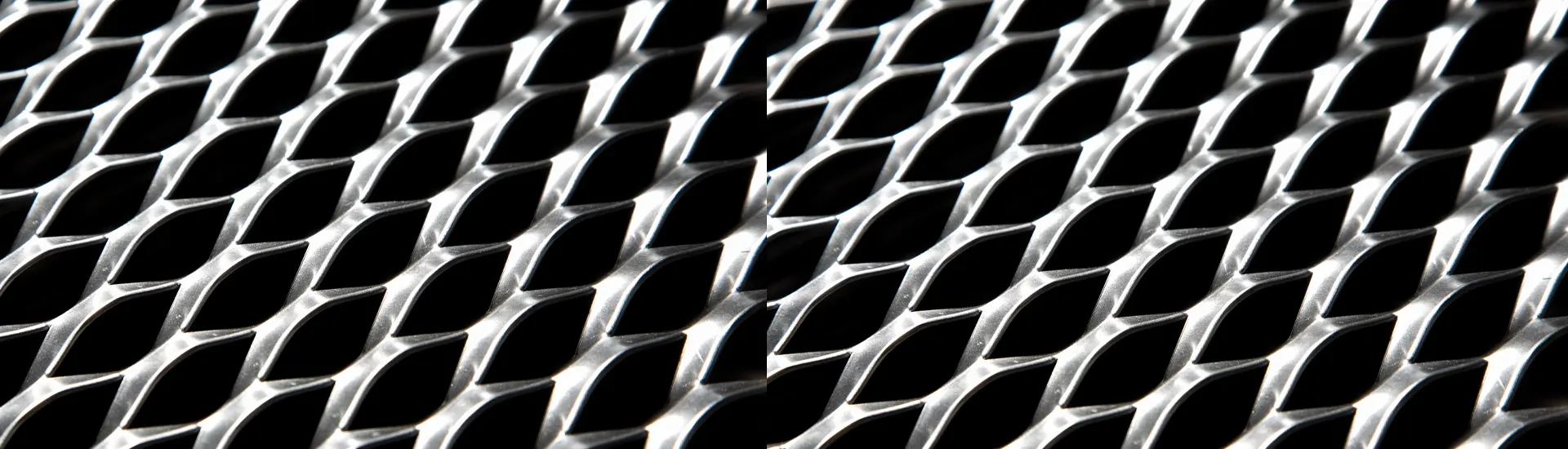

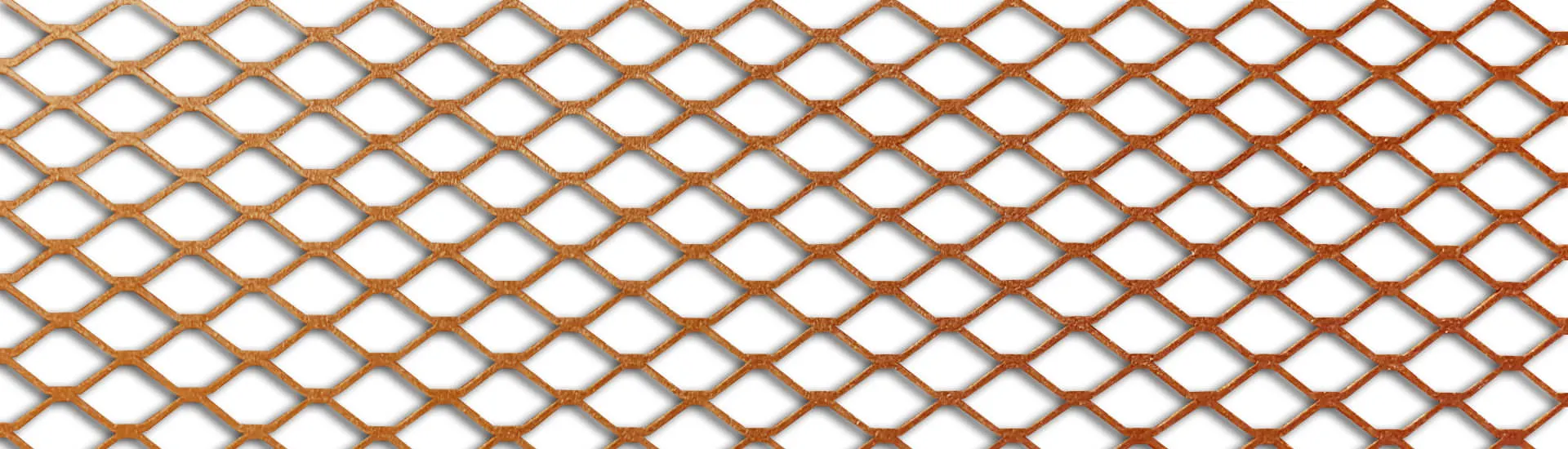

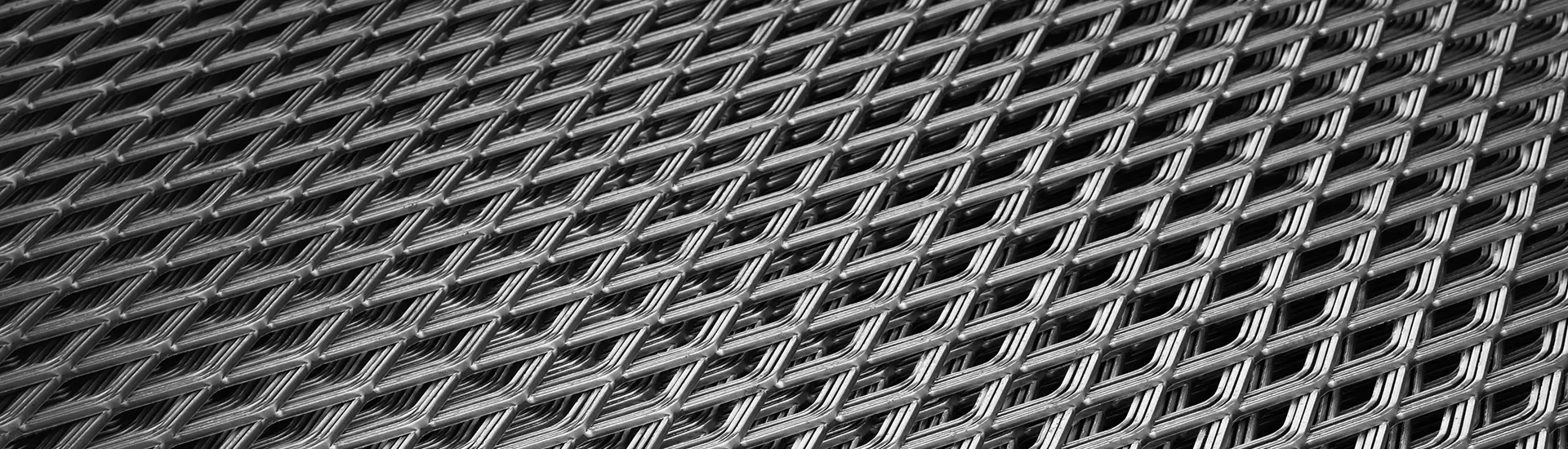

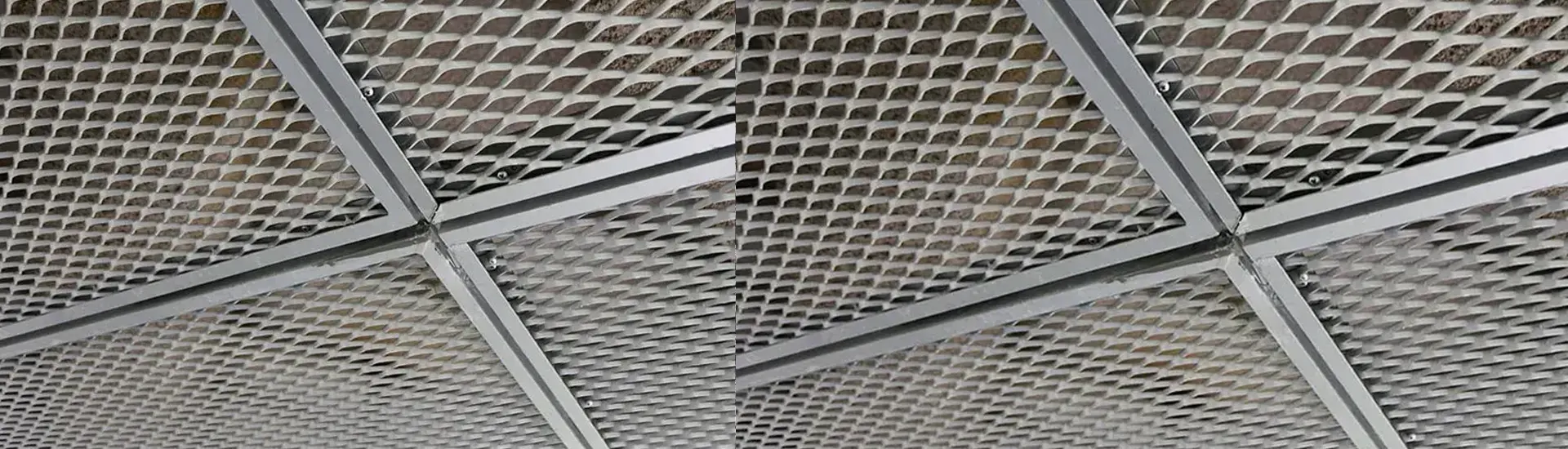

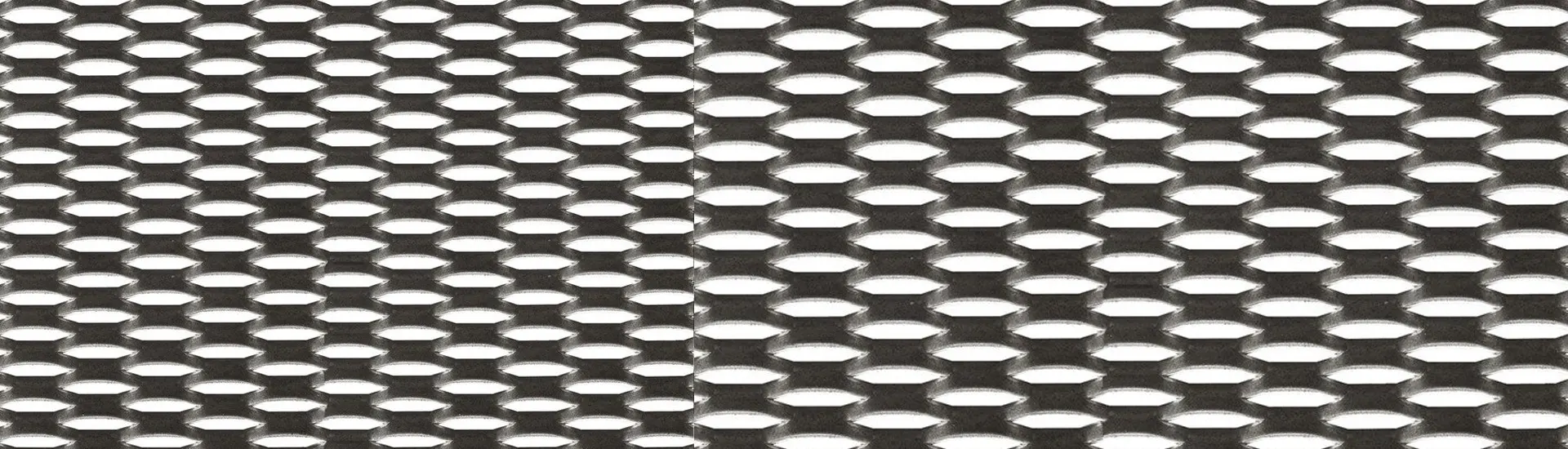

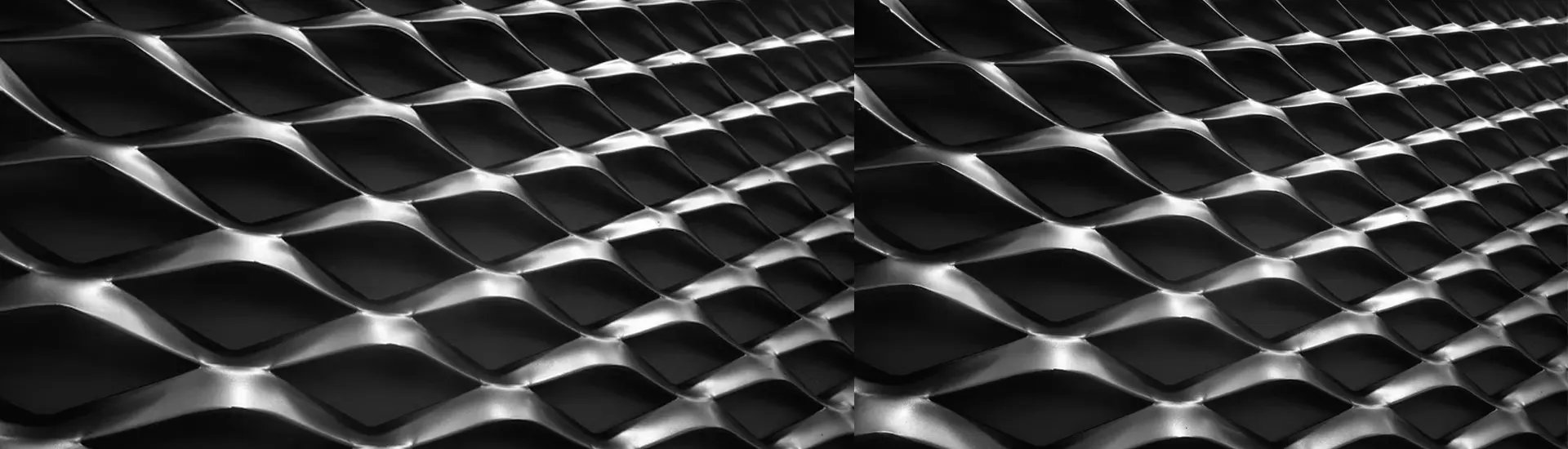

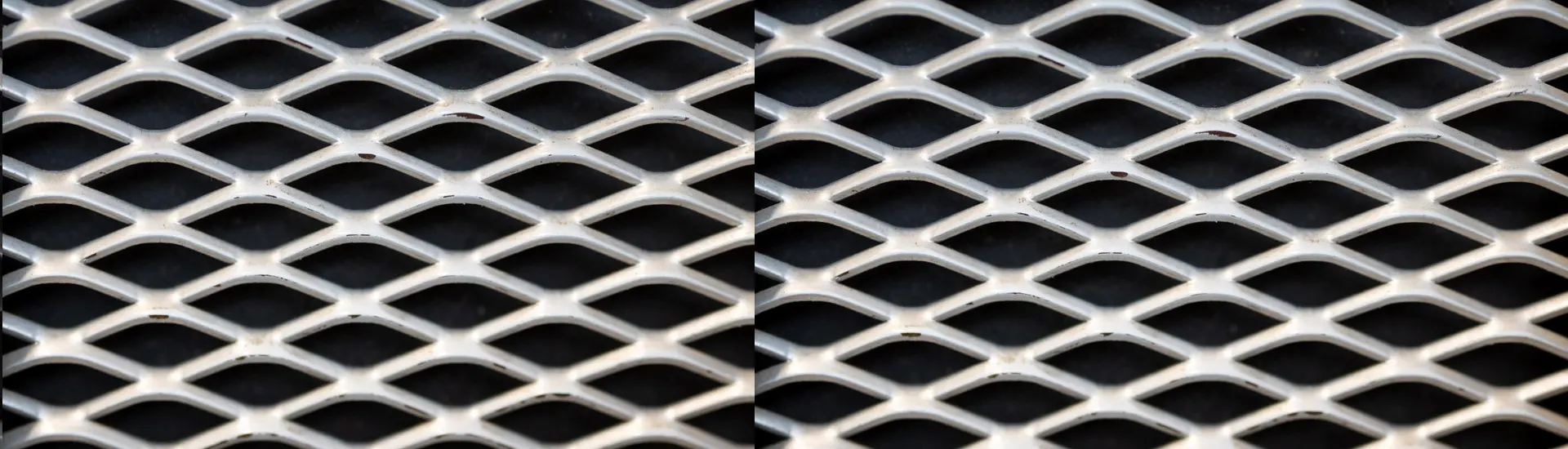

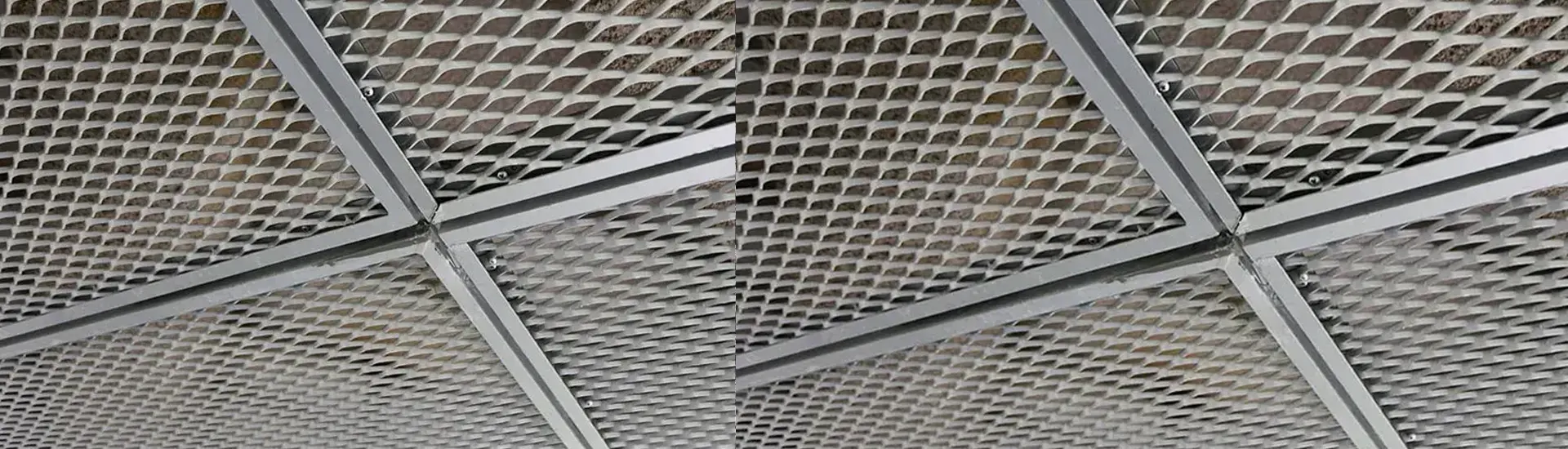

Aluminum expanded metal facade mesh is produced from a single piece of metal by stretching and forming various shapes such as diamond, hexagonal, square, and more in one step. It is widely used for the exterior facades of modern buildings including dining halls, airport terminals, shopping malls, theaters, museums, exhibition halls, and concert venues.

With its light weight and excellent corrosion resistance, aluminum expanded mesh is one of the most popular choices for architectural facades. Its non-slip surface and large openings allow good ventilation, creating a comfortable environment inside.

Available in various colors and finishes, aluminum expanded metal not only provides strength and durability but also adds an aesthetic appeal to building exteriors, making it the ideal option for decorative and functional facades.

Architectural expanded metals have a wide range of uses whether outdoors or indoors. It is commonly used in:

Micro aluminum expanded metal is being used as a filter or screen in automotive airbag and medical applications, as an acoustically neutral dent guard in audio speakers, and as an electrochemical conductor in new batteries.

Expanded metal fencing is broadly used in utilities, airports, roads and highways, playground, agricultural, livestock, retail stores, metropolitan housing, or as temporary fencing.

Expanded metal gates are widely applied to outdoor gates, such as gardens, courtyards, driveways, villas, houses, schools, garages, perimeters.

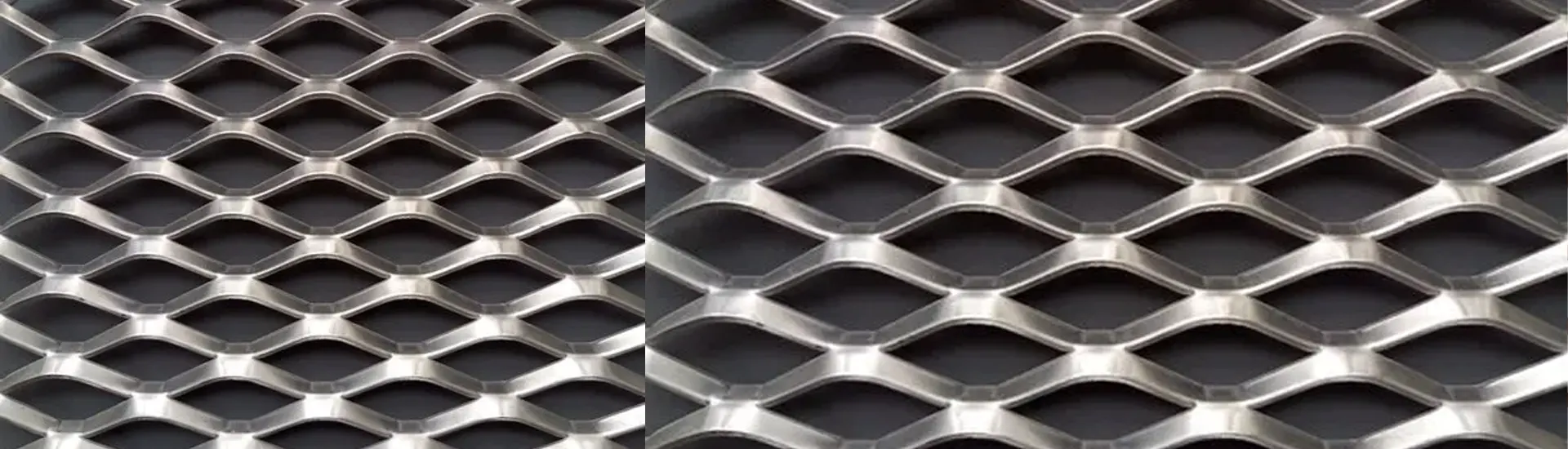

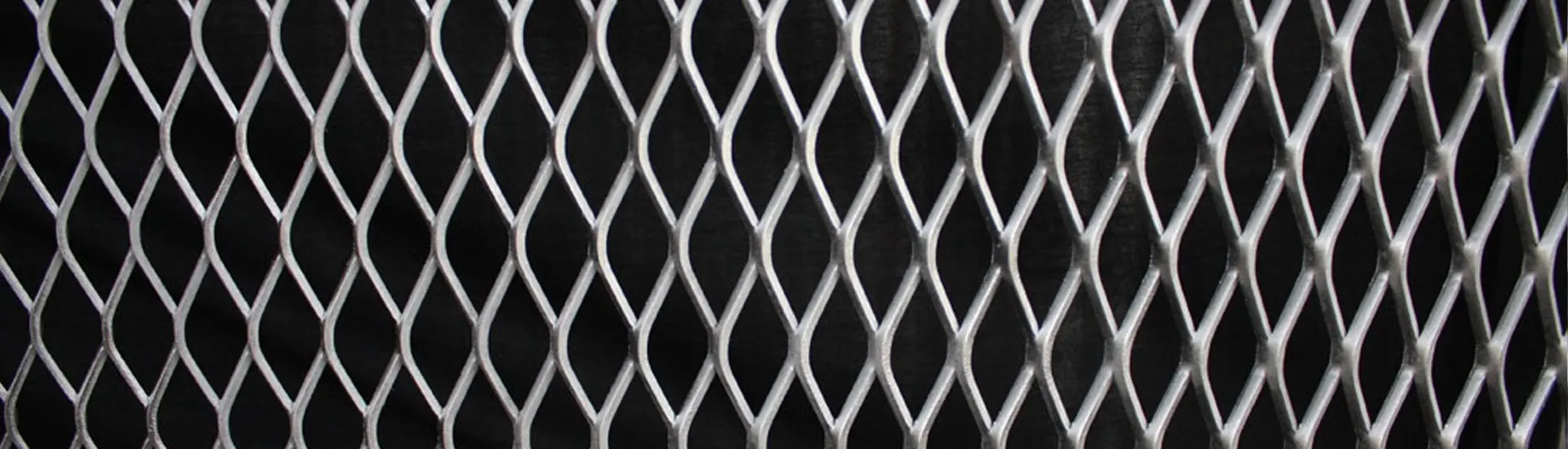

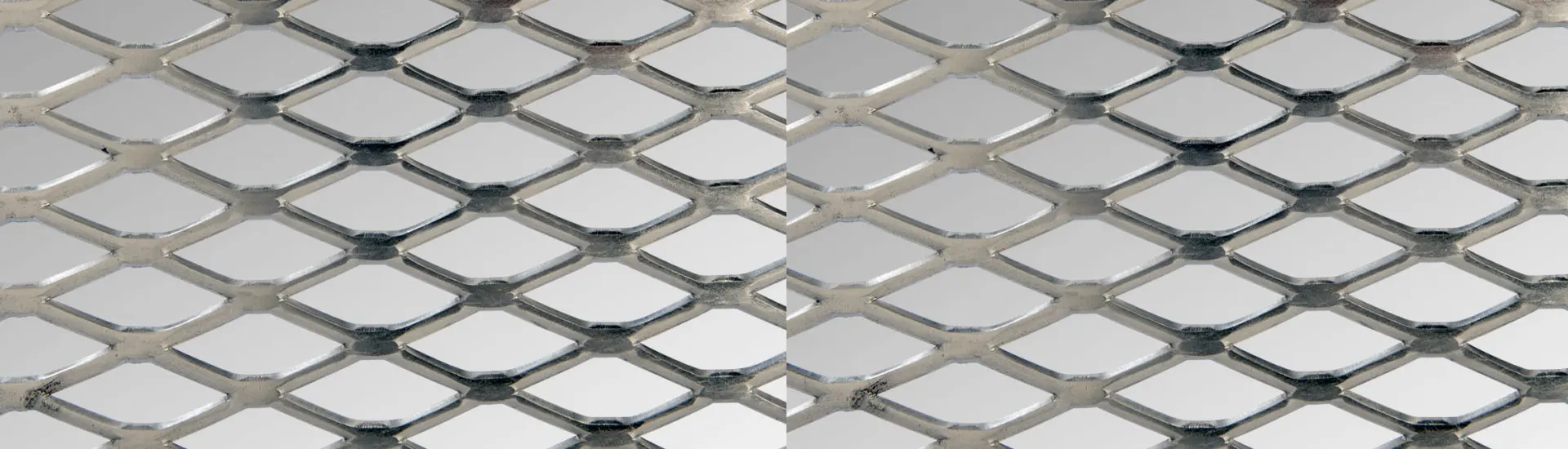

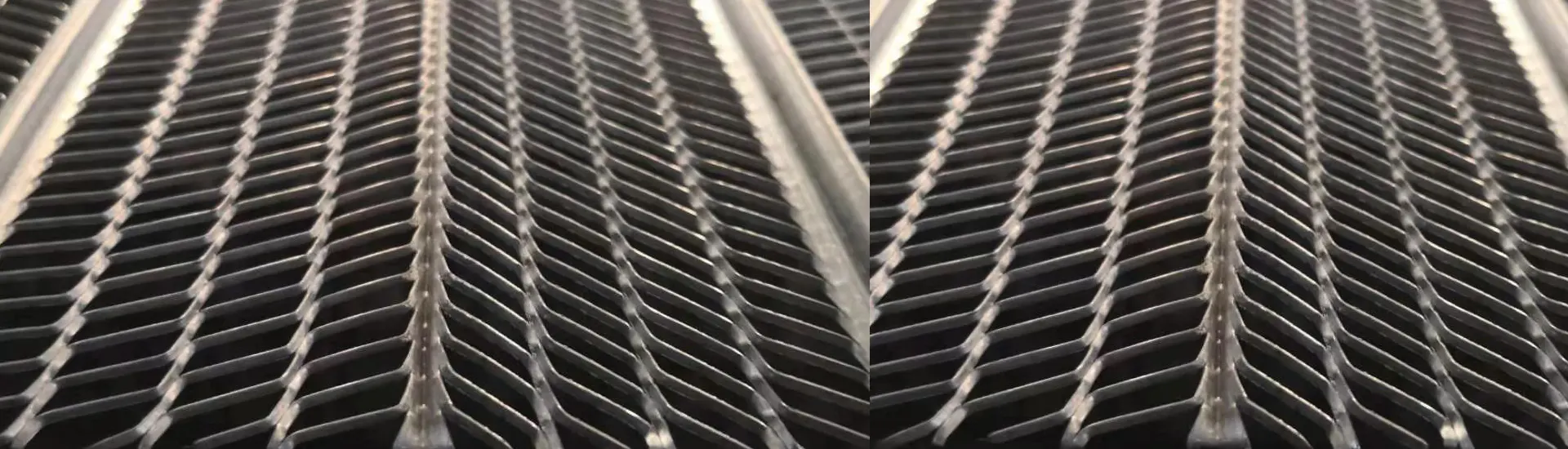

Flattened expanded metal, is manufactured by passing the metal through a cold roll reducing mill parallel to the LWD. It is Standard Expanded Metal that has been rolled through a flattening machine in the expanding process. By flattening the sheet, the bonds and strands are turned down to produce a smooth and flat surface – essentially elongating the LWD of the diamond. Flattened Expanded Metal with versatile and be bent or formed in any direction is used in billboard walkways, catwalks, stairs, drying racks, vents, ramps, walkways, flooring.

Hexagonal expanded metal mainly as heavy expanded metal are used in step mesh of oil tanks, working platforms, boilers, mine well, automobile vehicles, big ships, facades, roofs, fences, walkways; guarding of machines, making of security windows, road isolation, wall decoration; used with concrete, in buildings and construction, making of arts and crafts and as noise barrier for sound insulation or blinds for obstruction.

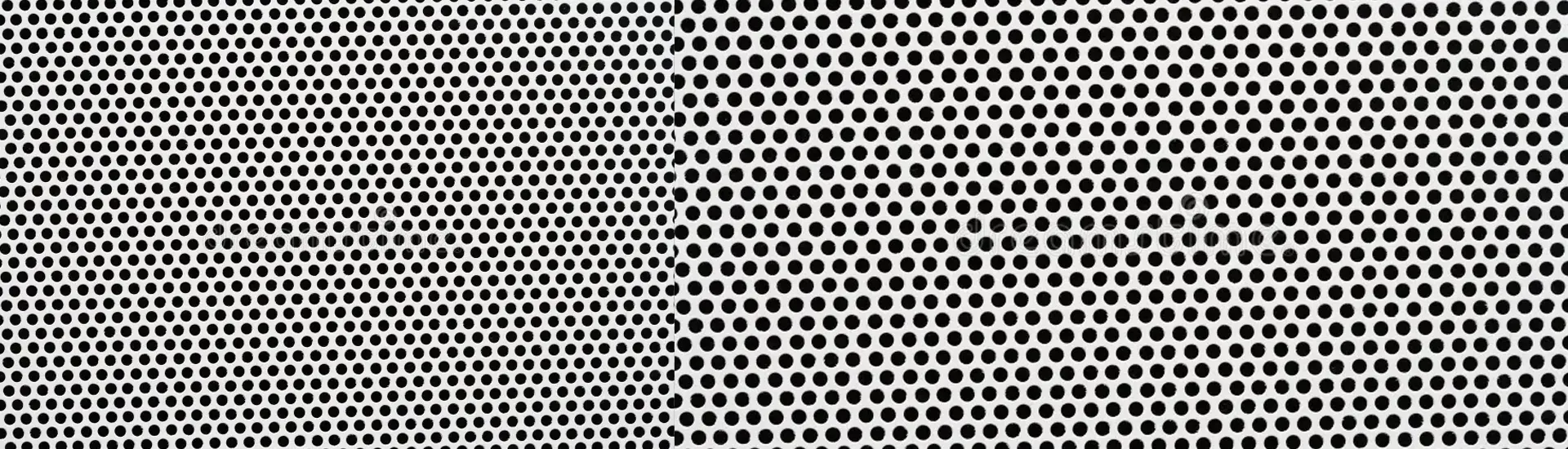

Corner bead, creates a rust proof, dent resistant finished corner. Expanded metal beads are available in multiple lengths to help reduce waste and minimize splicing. The intricate pattern of holes allows mud to penetrate through the bead to the drywall. The bead becomes part of the wall. Corner bead is general material for making corner cleaner and more beautiful. In addition to aesthetics, it can reinforce the wall at the same time, to avoid corner dents and other damage. With the shape of 90°, the corner beads can free slide between the floor and ceiling. Once aligning, it can be attached to the corner. Besides it provides a finish and protects external raked render angles. Expanded metal wings allowing for keying plaster up to the nose of the bead provide plumb reinforcement at corners.

Corner bead, creates a rust proof, dent resistant finished corner. Expanded metal beads are available in multiple lengths to help reduce waste and minimize splicing. The intricate pattern of holes allows mud to penetrate through the bead to the drywall. The bead becomes part of the wall. Corner bead is general material for making corner cleaner and more beautiful. In addition to aesthetics, it can reinforce the wall at the same time, to avoid corner dents and other damage. With the shape of 90°, the corner beads can free slide between the floor and ceiling. Once aligning, it can be attached to the corner. Besides it provides a finish and protects external raked render angles. Expanded metal wings allowing for keying plaster up to the nose of the bead provide plumb reinforcement at corners.

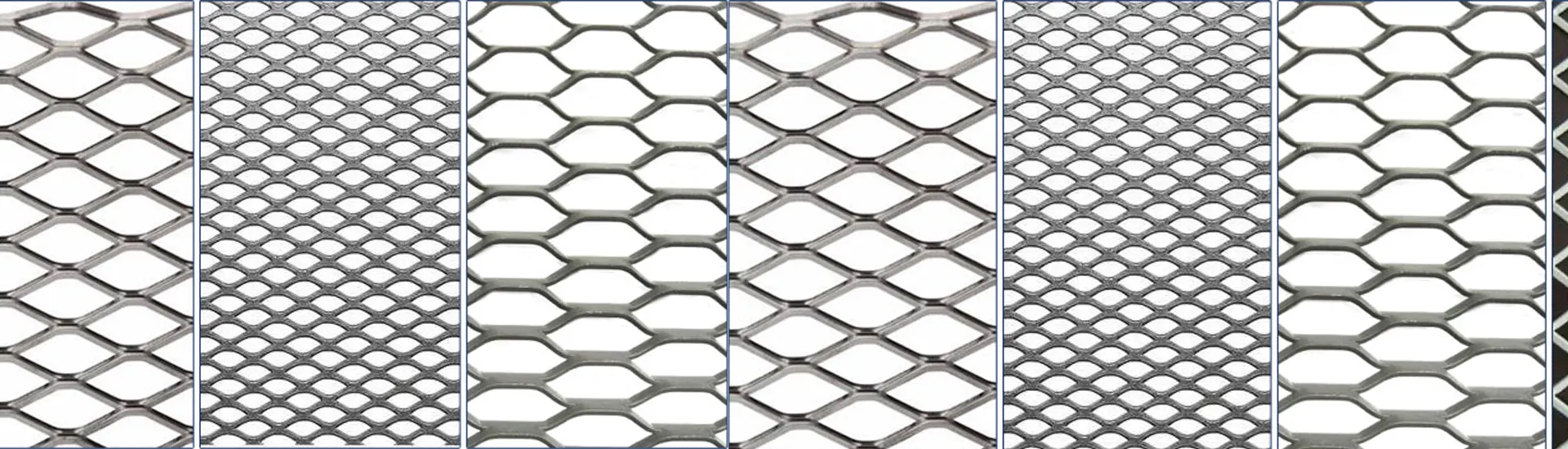

Expanded Metal, can be processed in different opening shapes, typically as: standard rhombic shape, heavy type tortoise-shaped, flattened expanded metal, and some special shapes or designs. Heavy type hexagonal shaped expanded metal, also known as among the tortoise-shaped expanded metal, is a heavy type expanded metal, reinforced compared with the regular expanded metal products. Heavy expanded metal is made of high quality plain steel after being expanded on the automatic expanded machines. Because of the high strength of heavy type expanded metal, it is mostly used as walkways, ramps and catwalks of all types.

As your one-stop manufacturing partner, Sunrise Industries maintains a complete inventory of ready-to-sell raw materials alongside custom parts fabrication and full engineering services. From prototyping to production, we provide everything at a single location—serving all industrial sectors and transforming manufacturing value chains.