Stainless steel forged bars and rods are widely used across industries due to their strength, precision, and resistance to corrosion. These products are especially suited for automotive, engineering, marine, and aerospace applications, offering excellent performance in demanding conditions. Available in a range of grades including stainless steel, duplex steel, and alloy steel, forged bars and rods are known for their dimensional accuracy, surface finish, and structural integrity.

These forged bars undergo multiple processing methods such as slotting, punching, machining, cutting, drilling, knurling, and more to match specific application requirements. Offered in various shapes and sizes, they can be customized for a variety of industrial uses. The products are manufactured under strict quality standards to ensure durability and resistance against harsh environments, making them suitable for both domestic and international markets.

The range includes Hastelloy C276 forged rods, super duplex steel bars, monel rods, copper-nickel rods, incoloy bars, and more. These forged products are exported to countries like Qatar, Kuwait, Saudi Arabia, and other Gulf and global regions. Their properties such as high tensile strength, resistance to oxidation, and excellent mechanical characteristics make them essential components in high-performance systems.

Clients can choose from custom sizes, finishes, and material grades based on project needs. Whether it’s a small quantity or bulk requirement, forged bars and rods are supplied as per specifications. Their adaptability to high temperatures and corrosive environments makes them a preferred choice for use in oil & gas, construction, shipbuilding, and heavy engineering industries.

Known for being specialists in forged products, suppliers offer nickel alloy forged bars, alloy 20 rods, inconel 600 forged bars, and titanium forged rods. With a strong distribution network and export expertise, forged bars are shipped to global destinations including the USA, Singapore, Russia, South Africa, Australia, and more. The combination of quality, customization, and delivery capabilities ensures continued trust from clients around the world.

ASTM A276, ASTM A484 SS 201, 202, 301, 302, 303, 304, 304H, 304L, 316, 316H, 316L, 309, 309S, 310, 310S, 316Ti, 317, 317L, 347, 321, 321H, 410, 416, 420, 430, 430F, 431, 440C, 630, 17-4PH, F51.

ASTM / ASME A815 UNS No. S31803, UNS No. S32205, UNS No. S31254, UNS No. S31550, UNS No. S32750, UNS No. S32760

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200), UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400), UNS 8020 (ALLOY 20 / 20 CB3), UNS 8825 (INCONEL 825), UNS 6600 (INCONEL 600), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276).

ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 (CU -NI- 90/10), C 71500 (CU -NI- 70/30)

Forged Bars are widely used in various industries due to their exceptional strength, dimensional accuracy, and resistance to wear and corrosion. Available in a broad range of sizes, grades, and finishes, these bars are ideal for applications in aerospace, oil & gas, marine, defense, automotive, and construction sectors. Each bar is precisely engineered to meet international standards and customer-specific requirements.

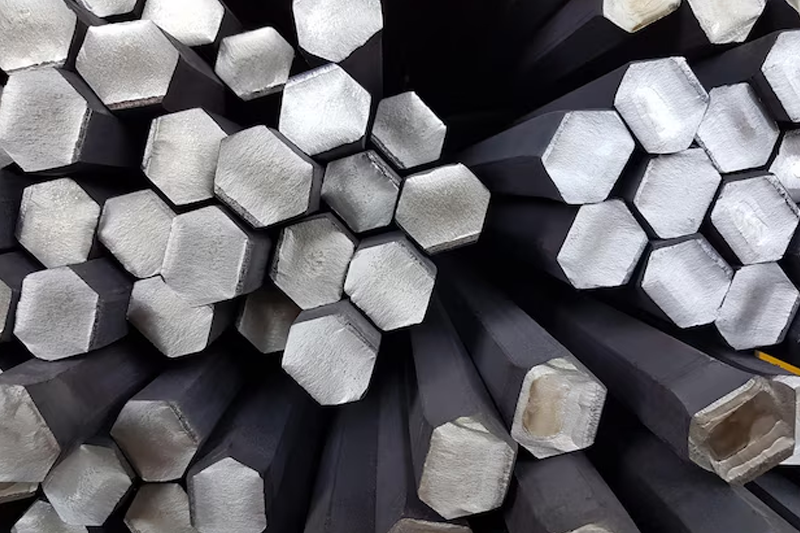

We offer forged bars in sizes ranging from 1mm to 450mm in diameter, with lengths from 1 meter to 6 meters, or as per customer needs. Our products meet major industry standards including ASTM, ASME, and API. We maintain tight tolerance levels following DIN 671 and ASTM A484, ensuring high performance and consistency. These bars are available in various finishes such as Bright, Black, Polish, Cold Drawn, Centreless Ground, and more. The form options include Round, Square, Hex, Rectangle, Coil Form, and Wire, offering maximum flexibility for end applications.

Our forged bars conform to NACE MR0175 / ISO 15156 requirements, making them suitable for use in sour gas environments and high-pressure applications. Each product is thoroughly inspected to ensure structural integrity, chemical consistency, and high mechanical strength.

Forged bars are essential components across various demanding industries due to their superior mechanical properties and corrosion resistance. They are commonly used in oil & gas plants, petrochemical industries, marine environments, defense equipment, power generation systems, and automotive components. Their ability to withstand high temperatures and pressures makes them an ideal choice for shafts, gears, flanges, fasteners, and connecting rods. With custom dimensions and excellent machinability, forged bars deliver reliable performance even in the harshest operating conditions.

Every forged bar undergoes stringent quality checks at every stage of manufacturing. We implement both destructive and non-destructive testing (NDT) to ensure compliance with international standards. This includes ultrasonic testing (UT), hardness tests, tensile strength, PMI (Positive Material Identification), and dimensional inspection. All testing is carried out by certified professionals to ensure that only defect-free, high-performance products reach our customers. Additionally, our production is aligned with ISO quality management systems, ensuring traceability and consistency in each batch.

As your one-stop manufacturing partner, Sunrise Industries maintains a complete inventory of ready-to-sell raw materials alongside custom parts fabrication and full engineering services. From prototyping to production, we provide everything at a single location—serving all industrial sectors and transforming manufacturing value chains.