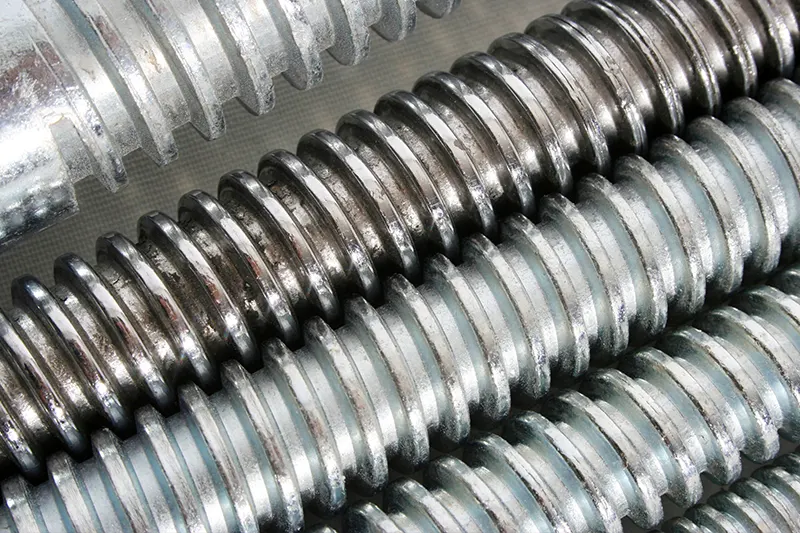

Threaded studs are widely used fastening components designed for creating strong and secure joints in various industrial, construction, and mechanical applications. They feature external threading along their length, enabling them to be paired with nuts or internally threaded components for a reliable connection. Studs are often used where a high level of clamping force or precision alignment is required, making them a preferred choice for machinery, automotive, and structural assemblies.

These studs are manufactured from a variety of high-quality materials such as stainless steel, carbon steel, alloy steel, duplex and super duplex steel, Monel, Inconel, Hastelloy, nickel alloys, copper-nickel alloys, and titanium, ensuring exceptional strength and corrosion resistance. The choice of material allows them to withstand demanding environments, including marine, chemical, and high-temperature applications.

A wide range of stud types is available to suit different fastening needs, including full threaded studs, double-end studs, half-threaded studs, and part-threaded studs. Each type serves specific purposes, whether for heavy-duty structural support, precise machinery alignment, or general-purpose fastening. These studs are engineered with precision threading to ensure smooth installation and secure connections.

Threaded studs can be customized in different lengths, diameters, thread pitches, and surface finishes to match project requirements. They are also available with various coatings such as zinc plating, hot-dip galvanizing, PTFE coating, or black oxide to enhance their durability and resistance to wear, corrosion, and harsh environmental conditions

These high-performance studs are supplied and exported to a wide range of industries and markets across Qatar, Bahrain, Saudi Arabia, Indonesia, Singapore, Malaysia, Turkey, UAE, Russia, Ukraine, South Africa, Australia, and the United States. Their reliability, strength, and versatile design make them an essential component for engineers and manufacturers worldwide.

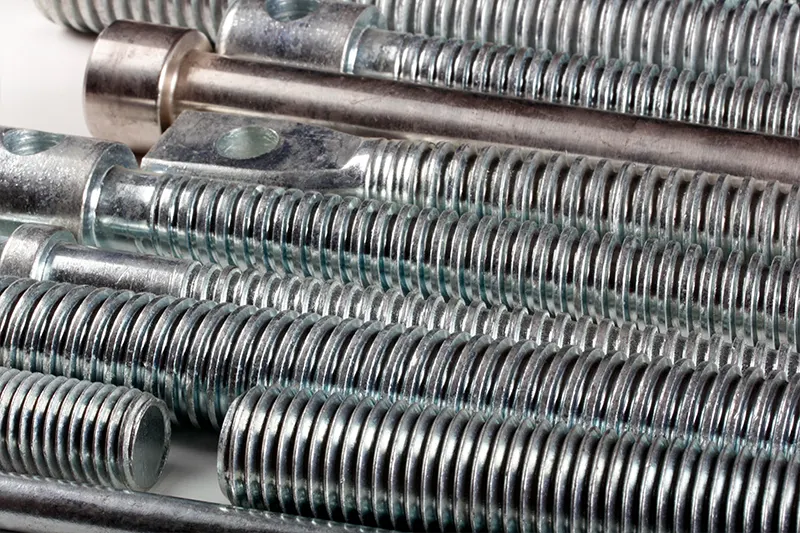

Full Threaded Stud

AISI 302, 304, 304L,316, 316L, 310, 317, 317L, 321, 347, 410, 420,904L etc.

ASTM / ASME A815 UNS No. S31803, UNS No. S32205, UNS No. S31254, UNS No. S31550, UNS No. S32750, UNS No. S32760

ASTM A307, A193

ASTM / ASME A/SA 193 / 194 B 6, B 7/ B 7M, B 16, 2, 2HM, 2H, GR 6, B 7, B 7M

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200), UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400), UNS 8020 (ALLOY 20 / 20 CB3), UNS 8825 (INCONEL 825), UNS 6600 (INCONEL 600), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276).

Threaded studs are manufactured in accordance with DIN, ASTM, BS, and other international standards, ensuring high precision, durability, and strength for various fastening applications. They are available in a wide size range from M3 to M56 (3/6” to 4”), with the option for customized dimensions to meet specific project needs. The length of these studs can vary from 3 mm to 3000 mm, making them suitable for both small-scale and heavy-duty industrial requirements.

A variety of stud types are available, including standard studs, full threaded studs, double-end threaded studs, rolled thread studs, and UNC threaded studs. Each type is designed for specific uses, offering reliable fastening solutions in construction, automotive, machinery, and industrial assemblies where high-strength and precise alignment are essential.

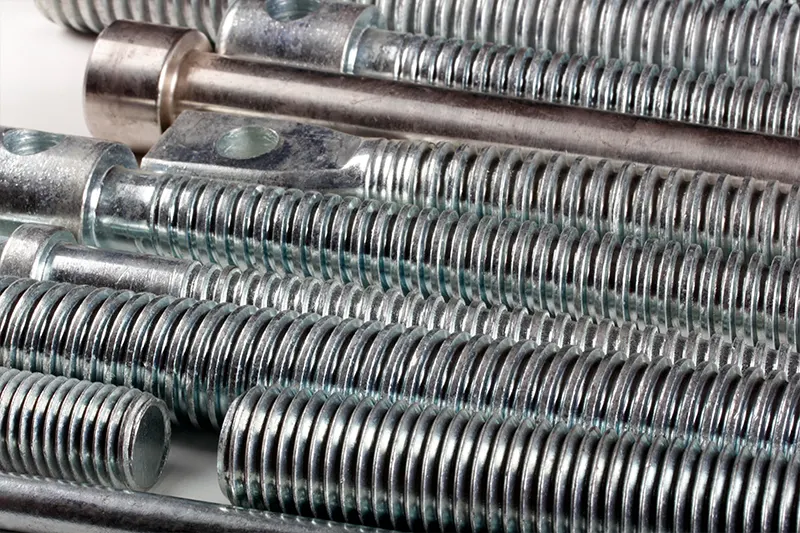

Threaded studs are designed and manufactured according to DIN, ASTM, BS, and other international standards, ensuring excellent quality, strength, and reliability. They are available in a size range from M3 to M56 (3/6” to 4”), with custom sizes also offered to suit specific project requirements. Their lengths vary from 3 mm to 3000 mm, making them ideal for both light-duty and heavy-duty industrial applications.

These fastening components are available in multiple types such as standard studs, full threaded studs, double-end threaded studs, rolled thread studs, and UNC threaded studs. Each type is engineered for different applications, providing secure and durable connections in construction, machinery, automotive, and various industrial assemblies.

As your one-stop manufacturing partner, Sunrise Industries maintains a complete inventory of ready-to-sell raw materials alongside custom parts fabrication and full engineering services. From prototyping to production, we provide everything at a single location—serving all industrial sectors and transforming manufacturing value chains.