ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H,904L

ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91

ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F70, ASTM A350, LF2, LF3

ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61, 2205 (UNS No. S31803), 2507 (UNS No. S32750)

UNS No. C 10100, 10200, 10300, 10800, 12000, 12200, 70600, 71500, UNS No. C 70600 (Cu -Ni- 90/10), C 71500 (Cu -Ni- 70/30)

ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020).

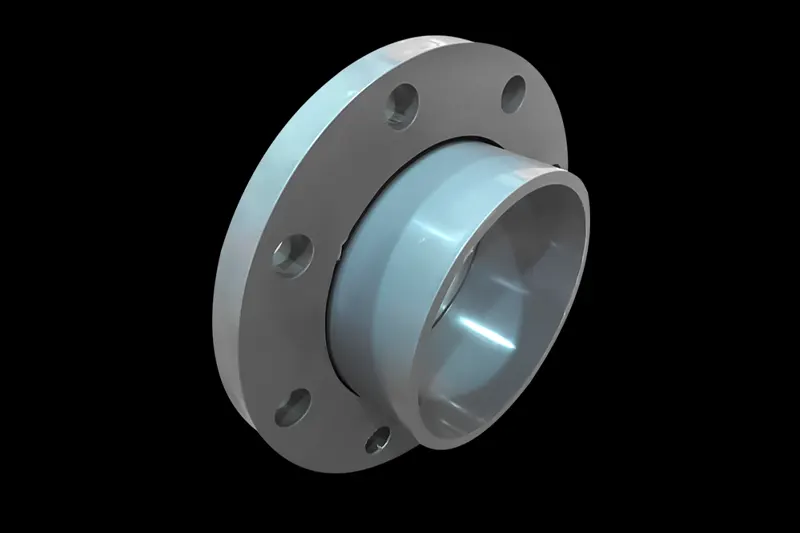

sunriseindustries offers high-quality Groove & Tongue Flanges that provide reliable sealing and perfect alignment for piping systems in critical environments. These flanges are ideal for high-pressure and high-temperature applications where welding is not preferred. Designed as per international standards like ANSI B16.5 and B16.47, our flanges are manufactured using premium materials such as Stainless Steel, Carbon Steel, Duplex, Inconel, and more—ensuring strength, corrosion resistance, and long service life in oil & gas, petrochemical, and power generation industries.