Hastelloy C2000 fasteners are highly durable components designed to meet the demanding needs of various industrial applications. These fasteners, made from a nickel-molybdenum-chromium alloy, offer exceptional corrosion resistance, making them suitable for both oxidizing and reducing environments. With improved fabricability, they do not require solution heat treatment after welding, making them more versatile and reliable for critical uses. Their excellent resistance to localized corrosion, such as pitting and crevice corrosion, further enhances their performance in harsh conditions.

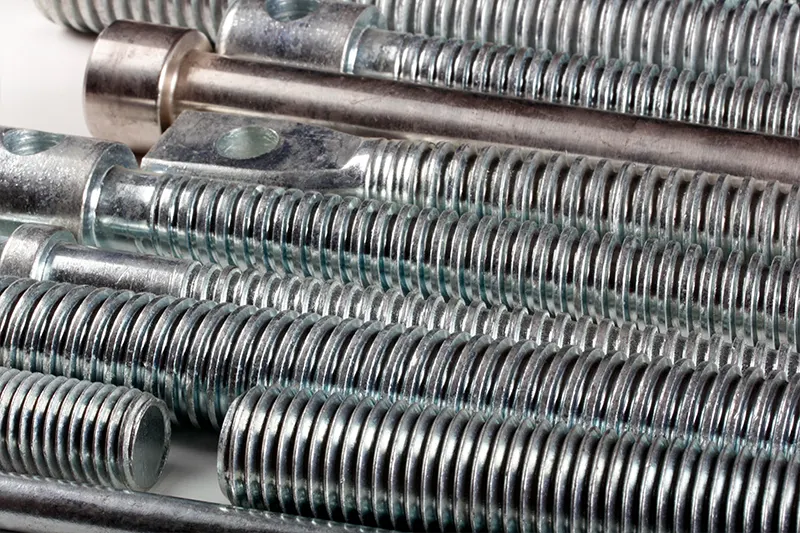

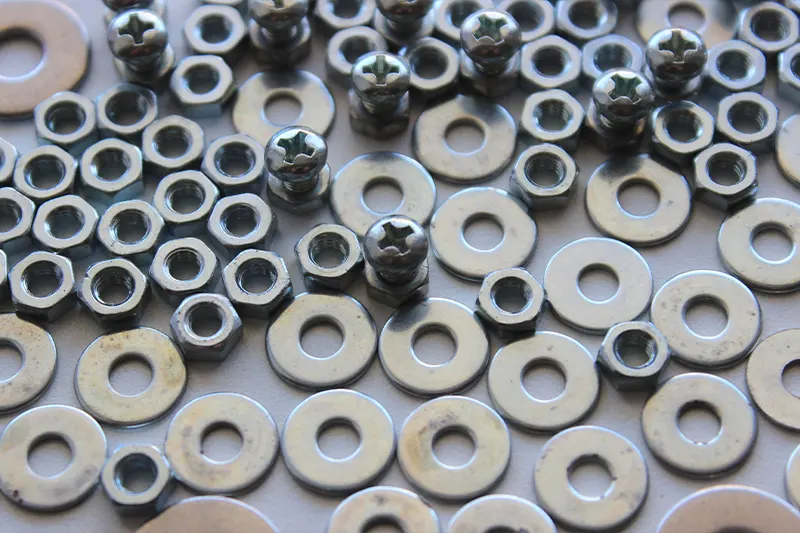

These fasteners are available in a wide range of types, including hex head bolts, nuts, washers, threaded rods, studs, anchor bolts, and machine screws, catering to different fastening requirements. They are designed and manufactured according to international standards like ASTM B574, DIN 2.4675, and UNS N06200, ensuring consistency and quality. With customizable sizes and shapes, Hastelloy C2000 fasteners can be tailored to meet specific project needs, offering a balance of strength, durability, and ease of installation.

Hastelloy C2000 fasteners are widely used in industries such as chemical processing, marine, oil and gas, and power generation, where high resistance to aggressive media is essential. Their superior mechanical properties and corrosion resistance make them ideal for equipment exposed to extreme temperatures, acids, and chlorides. Additionally, their robust design ensures reliable performance even under high stress and pressure conditions, reducing the risk of failure in critical applications.

These fasteners are also recognized for their innovative design and integration of modern manufacturing processes, ensuring high functionality and superior performance. They are available in standard as well as custom sizes to suit different requirements, offering flexibility in application. Moreover, their smooth surface finish and precise threading make them easy to install, providing long-term service with minimal maintenance.

Globally exported, Hastelloy C2000 fasteners are trusted by industries across Qatar, Bahrain, Saudi Arabia, Indonesia, the United States, Singapore, Malaysia, Turkey, UAE, Russia, Ukraine, South Africa, Australia, and more. Their exceptional quality and cost-effective pricing make them a preferred choice for customers seeking reliable fastening solutions in corrosive environments.

Hastelloy C2000 UNS N06200 Industrial Fasteners Manufacturer

| Standard | WERKSTOFF NR. | UNS | AWS | AFNOR | OR | JIS | BS | EN |

|---|---|---|---|---|---|---|---|---|

| Hastelloy C2000 | 2.4675 | N06200 | 055 | -- | -- | -- | -- | NiCr23Mo16Cu |

| Grade | Ni | Mo | C | P | Al | Mn | S | Si | Fe | Co | Cr | Cu |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hastelloy C2000 | Bal. | 15.0 - 17.0 | 0.10 max | 0.025 max | 0.5 max | 0.5 max | 0.01 max | 0.08 max | 3.0 max | 2.0 max | 22.0 - 24.0 | 1.3 - 1.9 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2% Offset) | Elongation |

|---|---|---|---|---|

| 8.5 g/cm³ | 1065 °C (1950 °F) | 752 MPa (109.0 ksi) | 358 MPa (52.0 ksi) | 64% |

Hastelloy C2000 industrial fasteners are widely used for their exceptional corrosion resistance in both oxidizing and reducing environments. These fasteners are made from a nickel-molybdenum-chromium alloy with additional copper, enhancing their resistance to localized corrosion such as pitting and crevice attacks. With superior mechanical properties, they perform reliably in harsh chemical and marine applications, making them ideal for industries like oil and gas, petrochemicals, and marine engineering.

These fasteners offer excellent mechanical strength, with a tensile strength of 752 MPa and a high yield strength, ensuring durability even in demanding conditions. They maintain their structural integrity at elevated temperatures and are easy to fabricate without the need for post-weld heat treatment. Available in various types such as bolts, nuts, washers, and threaded rods, Hastelloy C2000 fasteners are designed to meet international standards like ASTM, DIN, and BS, ensuring quality and reliability.

As your one-stop manufacturing partner, Sunrise Industries maintains a complete inventory of ready-to-sell raw materials alongside custom parts fabrication and full engineering services. From prototyping to production, we provide everything at a single location—serving all industrial sectors and transforming manufacturing value chains.