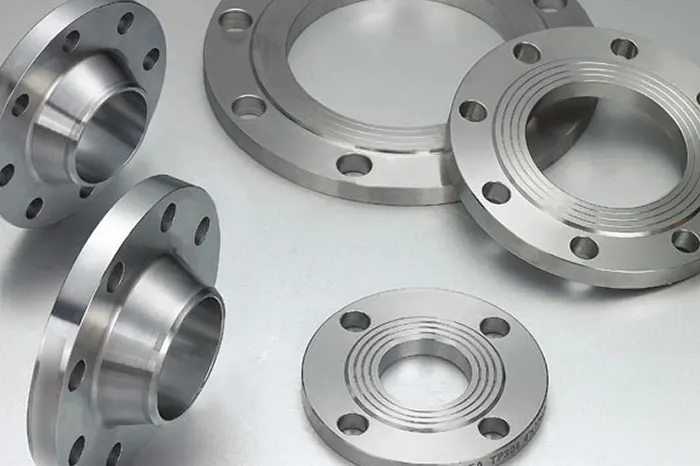

Hastelloy C276 Flanges are highly demanded for their excellent resistance to pitting, stress-corrosion cracking, and oxidizing environments. These flanges are widely used in chemical process industries, marine engineering, and power plants due to their superior durability. They also resist the formation of grain-boundary precipitates, making them suitable for welded conditions. At Sunrise Industries, customers can get these flanges in different sizes, types, and standards to meet industrial requirements. Their robust design and long-lasting performance ensure reliability in harsh operating environments. Hastelloy C276 Flanges are a preferred choice where strength and corrosion resistance are the key requirements.

Hastelloy C276 Flanges are designed with outstanding resistance against corrosion, making them suitable for aggressive chemical environments. They offer superior performance in seawater, acidic solutions, and high-temperature conditions. These flanges are manufactured to meet global standards like ANSI, ASTM, and ASME, ensuring high precision and strength. With excellent weldability, they minimize the risk of grain-boundary precipitation, which enhances their reliability in welded applications. At Sunrise Industries, customers can choose from different types like blind flanges, weld neck, socket weld, and orifice flanges. Their high mechanical strength and long service life make them ideal for critical applications.

Hastelloy C276 Flanges provide unmatched resistance against localized corrosion such as pitting and crevice attacks. They are ideal for use in chemical plants, desalination projects, marine operations, and nuclear power facilities. Their high tensile strength and toughness under pressure make them highly reliable in challenging environments. These flanges are available in different grades, pressure ratings, and specifications to suit diverse industrial needs. At Sunrise Industries, Hastelloy C276 Flanges are supplied with excellent finishing and quality standards. Their adaptability and superior corrosion resistance make them an economical solution for industries demanding reliable piping connections.

Advantages of Hastelloy C276 Flanges

ASTM B564 Hastelloy C276 Industrial Flanges Specification:-

Grades : Hastelloy C276 (UNS No. N10276)

Standards: ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

Specifications: ASTM B 564 / ASME SB 564

Size: 1/ 4″ NB TO 60″ NB

Class: 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, PN 6, PN10, PN20, PN40, PN60 With Table…

Wall Thickness: From 2 to 40 mm.

Schedule: 5S, 10S, 10, 20, 40S, 40, STD, 60, 80S, 80, XS, 100, 120, 140, 160, and XXS

Form: Slip On (SORF), WNRF, Blind, Socket Weld, Orifice, WNRTJ, BLRTJ, Threaded, Groove & Tongue, Lap Joint, Square Flanges & As Per Clients Required.

Flanges Face Type: Flat Face (FF), Raised Face (RF), Ring Type Joint (RTJ).

Our Hastelloy C276 Flanges Fittings conforms to NACE MR0175/ISO 15156.

| Standard | WERKSTOFF NR. | UNS | GOST | AFNOR | OR | JIS | BS | EN |

|---|---|---|---|---|---|---|---|---|

| Hastelloy C276 | 2.4819 | N10276 | ХН65МВУ | --- | ЭП760 | NW 0276 | --- | NiMo16Cr15W |

| Grade | Ni | Mo | Fe | C | P | Mn | S | Si | Co | W | Cr | V |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hastelloy C276 | Bal. | 15.0 - 17.0 | 4.0 - 7.0 | 0.01 max | 0.04 max | 1.0 max | 0.03 max | 0.08 max | 2.5 max | 3.0 - 4.5 | 14.5 - 16.5 | 0.35 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2% Offset) | Elongation |

|---|---|---|---|---|

| 8.89 g/cm³ | 1370 °C (2500 °F) | Psi – 1,15,000 , MPa – 790 | Psi – 52,000 , MPa – 355 | 40 % |

Hastelloy C276 Flanges come in different categories such as slip-on flanges, weld neck flanges, socket weld flanges, threaded flanges, and spectacle blind flanges. Each type is designed for specific applications, offering excellent versatility in industries like chemical processing, oil refining, and marine engineering. These flanges ensure leak-proof connections and long-lasting performance under extreme working conditions. Manufactured with precision and international compliance, they deliver superior strength and corrosion resistance. At Sunrise Industries, Hastelloy C276 Flanges are available in various dimensions, thicknesses, and pressure ratings, making them a dependable choice for global industries.

| Hastelloy C276 Flanges Supplier in Libya | C276 Hastelloy Square Flanges Manufacturer |

| Hastelloy Alloy C276 Din Flanges Exporter in Chile | ANSI B16.5 Hastelloy C276 Flat Flanges Exporter |

| Hastelloy UNS N10276 ANSI standard Flanges | Hastelloy C276 BLRF Flanges Trader in Ethiopia |

| Hastelloy Werkstoff Nr. 2.4819 Plate Flanges in Nigeria | Hastelloy C276 Orifice Flanges Supplier in Brazil |

| Hastelloy JIS NW 0276 Slip on Flanges Dealer in Africa | Hastelloy Alloy C276 Raised face Flanges in Zambia |

| C276 Hastelloy Alloy Lap joint Flanges Stockiest | Hastelloy C276 Welding Neck Flanges Dealer in Algeria |

| ASME SB564 Alloy C276 Reducing Flanges in Tanzania | C276 Hastelloy Alloy SORF Flanges in South Africa |

| ASTM B564 Hastelloy Alloy C276 Blind Flanges | Alloy C276 Hastelloy Pipe Flanges Stockiest in Egypt |

| C276 Hastelloy Alloy Screwed Flanges in Peru | Hastelloy C276 Forged Flanges Manufacturer in Ghana |

| Hastelloy C276 Industrial Flanges in Madagascar | C276 ASTM B564 Spectacle Flanges Stockholder |

| Hastelloy C276 B564 Ring Type Joint Flanges | Hastelloy Alloy C276 Socket Weld Flanges Suppliers |

| UNS N10276 Forged Socketweld Flange Supplier | N10276 Threaded Flanges Supplier in Brazil |

As your one-stop manufacturing partner, Sunrise Industries maintains a complete inventory of ready-to-sell raw materials alongside custom parts fabrication and full engineering services. From prototyping to production, we provide everything at a single location—serving all industrial sectors and transforming manufacturing value chains.