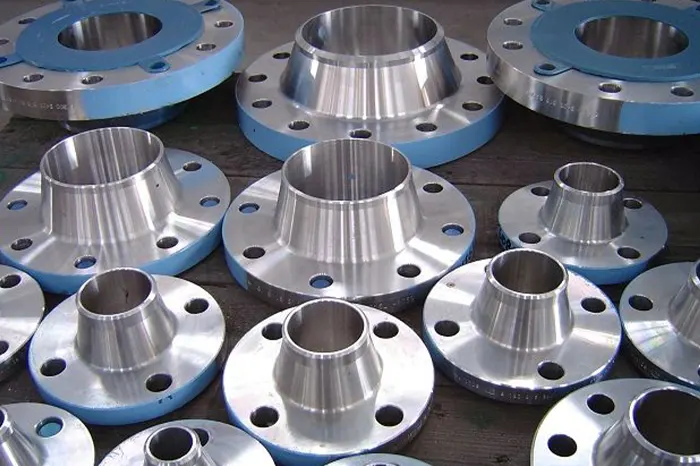

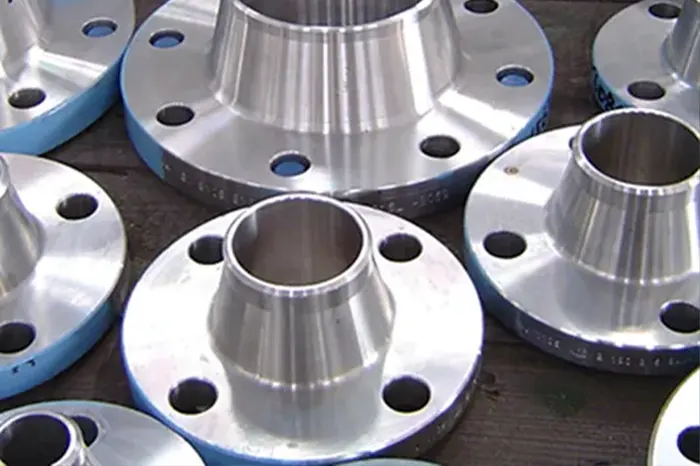

Inconel 600 (UNS N06600 / WNR 2.4816) Flanges are premium quality nickel-chromium-iron alloy components designed to deliver superior strength and durability in demanding industrial environments. Known for their excellent resistance to oxidation, carburization, and corrosion, these flanges are widely used in high-temperature and high-pressure systems. Their metallurgical stability allows them to perform reliably in both reducing and oxidizing environments where stainless steels and other alloys fail. Inconel 600 flanges are also immune to chloride-ion stress corrosion cracking, making them suitable for chemical, marine, and nuclear applications. With a combination of mechanical strength, thermal stability, and long service life, these flanges are trusted in critical operations where safety, reliability, and performance are of utmost importance.

Inconel 600 flanges are produced according to international quality standards to ensure precision and reliability. These include ASTM B564, ANSI B16.5, ASME 16.47 Series A & B, and MSS-SP-44, making them suitable for diverse industrial applications worldwide. The material designation UNS N06600 and DIN 2.4816 ensures global recognition and standardization. By following these specifications, each flange guarantees dimensional accuracy, durability, and interchangeability with other standard piping components.

Compliance with international standards also ensures that the flanges meet stringent performance and safety requirements, providing assurance to engineers and industries alike. Whether used in slip-on, weld neck, blind, or threaded form, these flanges deliver consistent performance while adhering to recognized codes and regulations across multiple industries.

One of the most valuable properties of Inconel 600 flanges is their exceptional corrosion resistance across a wide range of environments. They offer superior protection against oxidation, carburization, and scaling at high temperatures. Additionally, they resist the effects of dry chlorine and hydrogen chloride gases at moderately elevated conditions, making them ideal for chemical industries. Their immunity to chloride-ion stress corrosion cracking further enhances their performance in marine and offshore applications where exposure to seawater and aggressive agents is common. These flanges also resist attack from caustic solutions and many organic and inorganic chemicals. This broad resistance to both oxidizing and reducing agents makes Inconel 600 flanges a preferred choice for industries that require long-term durability and minimal maintenance.

Specifications of Inconel 600 (UNS N06600) Flanges

Grades : Inconel 600 (UNS No. N06600)

Standards: ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

Specifications: ASTM B 564 / ASME SB 564

Size: 1/8″ TO 48″ NB

Class: 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64.

Wall Thickness: From 2 to 40 mm.

Schedule: Sch. 5 TO Sch. XXS.

Type: Flat Face (FF), Raised Face (RF), Ring Type Joint (RTJ).

Form: Slip On (SORF), WNRF, Blind, Socket Weld, Orifice, WNRTJ, BLRTJ, Threaded, Groove & Tongue, Lap Joint, Square Flanges & As Per Clients Required.

Our Inconel 600 Flanges Fittings conforms to NACE MR0175/ISO 15156.

| Standard | WERKSTOFF NR. | UNS | GOST | AFNOR | JIS | BS | EN |

|---|---|---|---|---|---|---|---|

| Inconel 600 | 2.4816 | N06600 | МНЖМц 28-2,5-1,5 | NC15FE11M | NCF 600 / ЭИ868 | NA 13 | NiCr15Fe |

| Grade | Ni | Fe | C | Mn | Si | Cu | Al | Ti | S |

|---|---|---|---|---|---|---|---|---|---|

| Inconel 600 | 72.0 min | 6.0 - 10.0 | 0.15 max | 1.00 max | 0.5 max | 0.5 max | - | - | 0.015 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2% Offset) | Elongation |

|---|---|---|---|---|

| 8.4 g/cm³ | 1370-1425 ℃ | 550 MPa min. | 240 MPa min. | 30% |

| Inconel 600 Flanges Supplier in Peru | Inconel 600 Square Flanges Manufacturer in India |

| Inconel Alloy 600 Din Standard Flanges Exporter | ANSI B16.5 Inconel 600 Flat Flanges Exporter |

| Inconel UNS N06600 ANSI standard Flanges in Chile | Inconel Alloy 600 BLRF Flanges in Madagascar |

| Inconel Werkstoff Nr. 2.4816 Plate Flanges | Inconel 600 Orifice Flanges Trader in Algeria |

| Inconel 600 Slip on Flanges Stockholder in Ghana | Inconel Alloy 600 Raised face Flanges in Egypt |

| Inconel Alloy 600 Lap joint Flanges Stockiest | Inconel 600 Welding Neck Flanges Trader in Africa |

| ASME SB 564 Inconel 600 Alloy Reducing Flanges | Inconel 600 SORF Flanges Distributor in Tanzania |

| ASTM B564 Inconel 600 Blind Flanges in Brazil | Inconel 600 Pipe Flanges in Zambia |

| B564 Inconel 600 Screwed Flanges Dealer in Nigeria | Inconel 600 Forged Flanges |

| Inconel Alloy 600 Industrial Flanges Exporter in Ethiopia | Inconel 600 ASTM B564 Spectacle Flanges |

| Inconel 600 Ring Type Joint Flanges in South Africa | Inconel 600 Socket Weld Flanges in Libya |

As your one-stop manufacturing partner, Sunrise Industries maintains a complete inventory of ready-to-sell raw materials alongside custom parts fabrication and full engineering services. From prototyping to production, we provide everything at a single location—serving all industrial sectors and transforming manufacturing value chains.