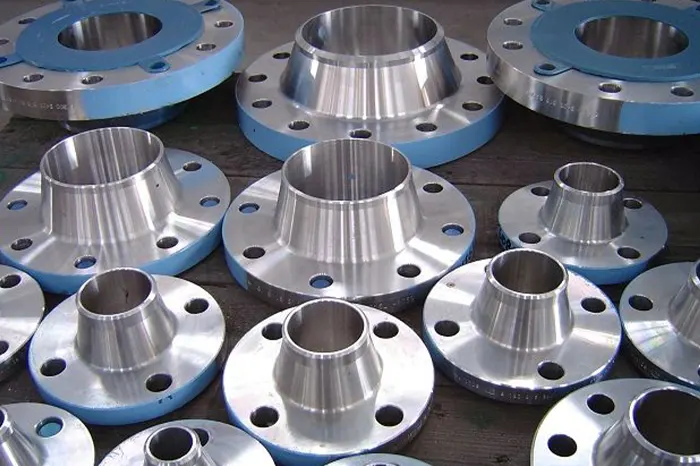

Sunrise Industries manufactures and exports Inconel 601 blind flanges known for their durability and resistance in high-temperature environments. These flanges are primarily used to terminate piping systems or pressure vessel openings, ensuring safety and efficiency in operations. Inconel 601 blind flanges provide excellent oxidation resistance up to 2000°F, making them suitable for petrochemical, power generation, and refining industries. Our blind flanges are produced as per ASTM B564 and ASME B16.47 standards, guaranteeing superior quality. Sunrise Industries supplies these flanges globally in standard and customized sizes, offering cost-effective pricing without compromising on durability or performance.

ASTM B564 Inconel 601 Industrial Flanges Specification

Grades : Inconel 601 (UNS No. N06601)

Standards: ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

Specifications: ASTM B 564 / ASME SB 564

Size: 1/8″ TO 48″ NB

Class: 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64.

Wall Thickness: From 2 to 40 mm.

Schedule: Sch. 5 TO Sch. XXS.

Type: Flat Face (FF), Raised Face (RF), Ring Type Joint (RTJ).

Form: Slip On (SORF), WNRF, Blind, Socket Weld, Orifice, WNRTJ, BLRTJ, Threaded, Groove & Tongue, Lap Joint, Square Flanges & As Per Clients Required.

Our Inconel 601 Flanges Fittings conforms to NACE MR0175/ISO 15156.

| Standard | WERKSTOFF NR. | UNS | GOST | AFNOR | OR | JIS | BS | EN |

|---|---|---|---|---|---|---|---|---|

| Inconel 601 | 2.4851 | N06601 | ХН60ВТ | NC23FeA | ЭИ868 | NCF 601 | NA 49 | NiCr23Fe |

| Grade | Ni | Fe | C | Mn | Si | Cu | Al | Cr | S |

|---|---|---|---|---|---|---|---|---|---|

| Inconel 601 | 61.5 min | Bal. | 0.05 max | 1.00 max | 0.5 max | 1.0 max | 1.0 - 1.7 | 21.0 - 25.0 | 0.015 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2% Offset) | Elongation |

|---|---|---|---|---|

| 8.4 g/cm³ | 1320-1370 ℃ | 650 MPa min. | 300 MPa min. | 30% |

| Inconel 601 Flanges Supplier in Ethiopia | Inconel 601 Square Flanges Manufacturer in India |

| Inconel Alloy 601 Din Standard Flanges Exporter | ANSI B16.5 Inconel 601 Flat Flanges Exporter |

| Inconel UNS N06601 ANSI standard Flanges Stockholder | Inconel Alloy 601 BLRF Flanges in Africa |

| Inconel DIN 2.4851 Plate Flanges Dealer in Ghana | Inconel 601 Orifice Flanges Supplier in Libya |

| Inconel Alloy 601 Slip on Flanges in South Africa | Inconel Alloy 601 Raised face Flanges |

| Inconel 601 Lap joint Flanges Stockiest in Brazil | Inconel 601 Welding Neck Flanges in Egypt |

| ASME SB 564 Inconel 601 Alloy Reducing Flanges | Inconel 601 SORF Flanges in Madagascar |

| ASTM B564 Inconel 601 Blind Flanges in Nigeria | Inconel 601 Pipe Flanges Dealer in Tanzania |

| Inconel 601 Alloy Screwed Flanges Supplier in Chile | Inconel 601 Forged Flanges Trader in Algeria |

| Inconel Alloy 601 Industrial Flanges in Peru | Inconel 601 ASTM B564 Spectacle Flanges |

| Inconel 601 Ring Type Joint Flanges | Inconel 601 Socket Weld Flanges in Zambia |

As your one-stop manufacturing partner, Sunrise Industries maintains a complete inventory of ready-to-sell raw materials alongside custom parts fabrication and full engineering services. From prototyping to production, we provide everything at a single location—serving all industrial sectors and transforming manufacturing value chains.