35+ materials & 8+ finishes

NADCAP & NABL approved partners

Laser, CMM & hand inspections

Hardware installation & assembly

| CNC Process | Max Length (mm) | Max Width (mm) | Max Height (mm) | Max Diameter (mm) |

|---|---|---|---|---|

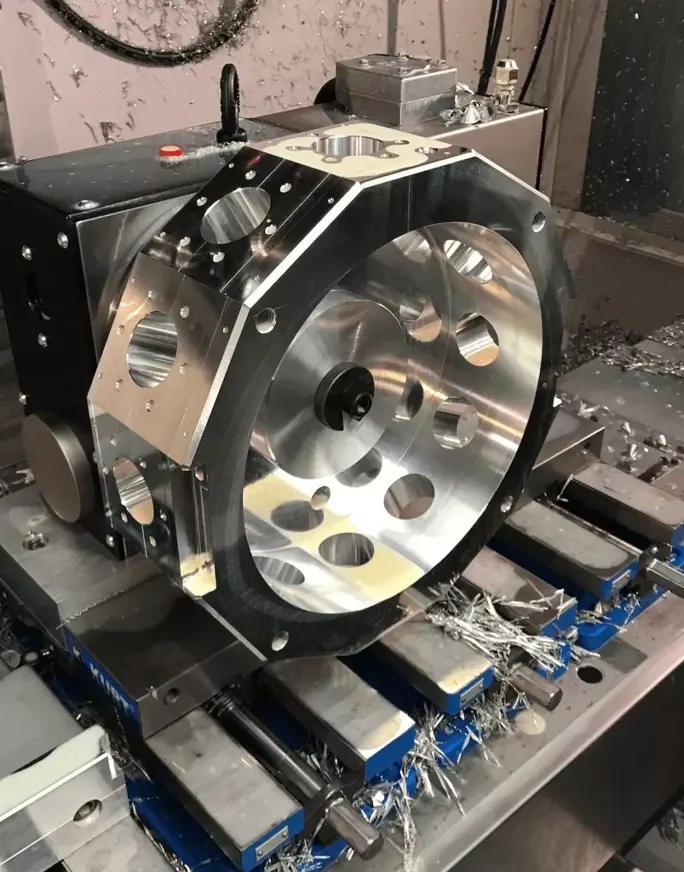

| Large CNC Mill | 10,500 | 3,700 | 1,200 | ---- |

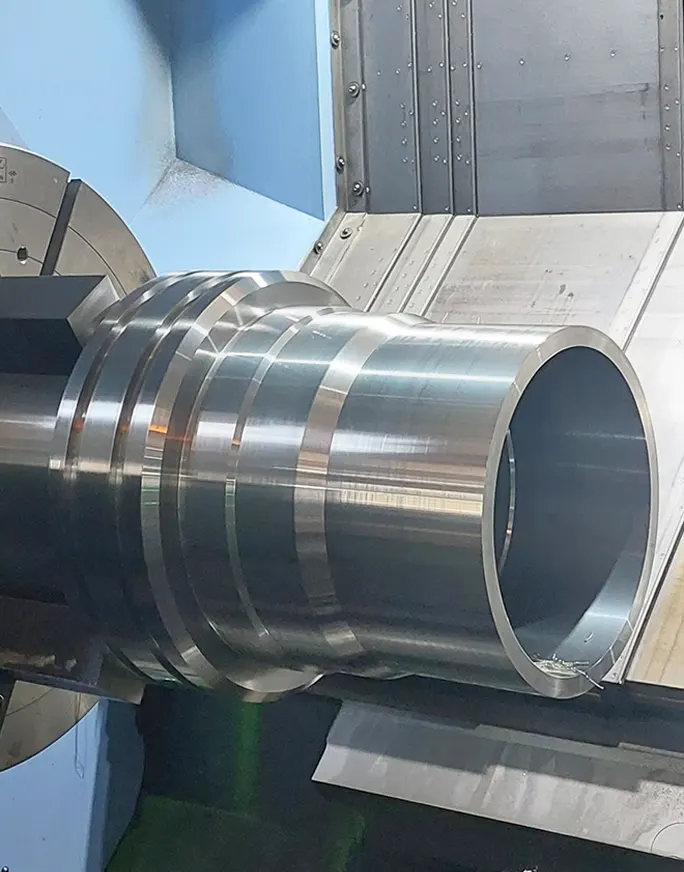

| Large Horizontal CNC Lathe | 10,500 | ---- | ---- | 2,500 |

| Large Vertical CNC Lathe | 1,600 | ---- | ---- | 2,500 |

Mill Lead Time: As fast as 3 days

As your one-stop manufacturing partner, Sunrise Industries maintains a complete inventory of ready-to-sell raw materials alongside custom parts fabrication and full engineering services. From prototyping to production, we provide everything at a single location—serving all industrial sectors and transforming manufacturing value chains.