Male Branch Tees are manufactured using premium-grade materials such as stainless steel, brass, or carbon steel. Stainless steel versions provide excellent corrosion resistance, making them ideal for chemical, marine, and outdoor environments. Brass tees are lightweight and resist rust, commonly used in plumbing and instrumentation. Carbon steel options are suitable for heavy-duty industrial applications where strength and durability under high pressure are essential.

These tees feature accurately machined male threads like NPT, BSPT, BSPP, or Metric standards, ensuring a reliable and leak-proof fit. The male threaded connection simplifies assembly, providing a tight seal in hydraulic, pneumatic, and fluid transfer systems. Their precise design reduces the risk of leaks, improves system efficiency, and enhances overall safety.

Male Branch Tees are widely used in diverse industries, including oil & gas, chemical processing, water treatment, power generation, and instrumentation. They are essential for creating branch lines from a main flow, allowing flexible routing of fluids or gases. Their robust design makes them suitable for both high- and low-pressure applications, from industrial machinery to commercial piping networks.

hanks to their threaded male connections, Male Branch Tees can be installed quickly without the need for welding or special tools. This reduces labor time and cost, making them ideal for modular piping systems. They can also be easily removed or replaced during routine maintenance, minimizing downtime and simplifying repairs in complex setups.

To ensure consistent quality and performance, Male Branch Tees are manufactured in compliance with ASTM, ASME, SAE, and ISO standards. This guarantees compatibility with other fittings and components, making them easy to integrate into existing systems. They undergo strict quality checks and pressure testing to ensure reliability in critical applications.

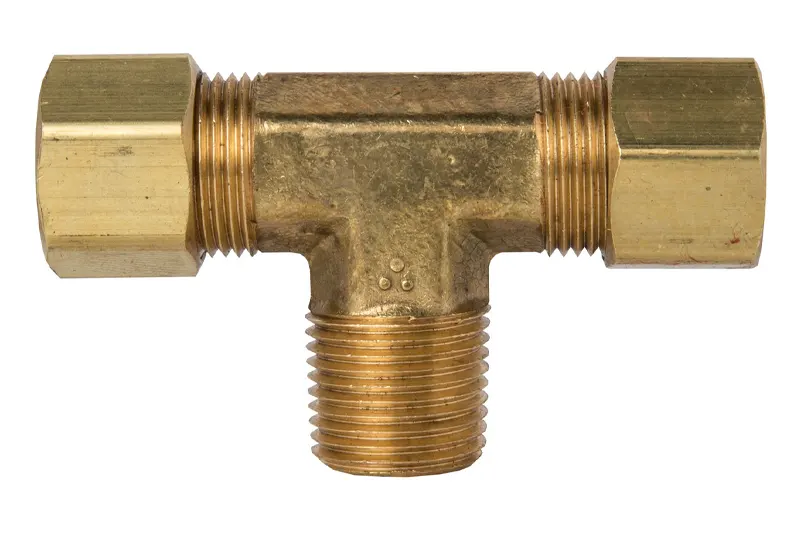

Male Branch Tee

Imperial Size: 1/4″ to 2″ NB

Metric Size: 6mm to 50mm

Imperial Size: 1/4″ to 2″ NB

Metric Size: 6mm to 50mm

Manufacturing Standard – ASTM

Dimensional Standard – ASME / ANSI B 16.9

| Type | Grade |

|---|---|

| Nickel Male Branch Tee | 200 & 201 |

| Monel Male Branch Tee | 400, R-405 & K-500 |

| Inconel Male Branch Tee | 600, 601, 625 & 718 |

| Incoloy Male Branch Tee | 800, 800H, 800HT, 825, 925 & DS |

| Hastelloy Male Branch Tee | B-2, B-3, C-22, C-276, C-2000 & X |

| Cupro Nickel Male Branch Tee | Cu Ni 90/10 (C71500) / Cu Ni 70/30 (C70600) |

| Duplex Male Branch Tee | S32205 / S31803 / S31550 / S31254 |

| Super Duplex Male Branch Tee | SAF 2507, Zeron 100 & Ferralium 255 |

| Alloy 20 Male Branch Tee | Alloy 20 / Carpenter 20 |

| 254 SMO Male Branch Tee | 254 SMO |

| 904L Male Branch Tee | SS 904L |

| Titanium Male Branch Tee | Gr.2 & Gr.5 |

| Nitronic Male Branch Tee | Nitronic 30, Nitronic50, Nitronic60 |

| Stainless Steel Male Branch Tee | 304, 304L, 316, 316L, 316H, 321, 321H, 347, 446 |

Male Branch Tees are crafted from high-quality stainless steel, brass, or carbon steel to ensure excellent strength, durability, and corrosion resistance. Their robust design makes them ideal for use in demanding industrial environments such as chemical processing, oil & gas, and water treatment applications.

These tees feature precision-engineered male threads like NPT, BSPT, or Metric, providing a tight and reliable seal. They allow smooth distribution of fluid or gas from the main line to the branch connection, making them suitable for hydraulic, pneumatic, and fluid transfer systems while ensuring easy installation and maintenance.

As your one-stop manufacturing partner, Sunrise Industries maintains a complete inventory of ready-to-sell raw materials alongside custom parts fabrication and full engineering services. From prototyping to production, we provide everything at a single location—serving all industrial sectors and transforming manufacturing value chains.