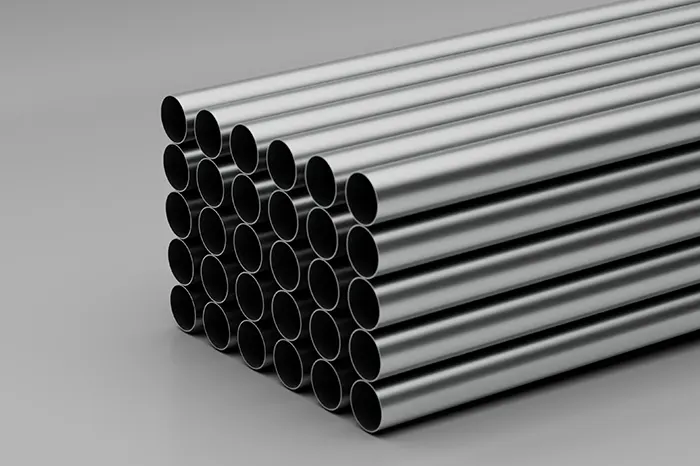

Monel 400 Flanges – High Strength & Corrosion Resistance

ASTM B161 Monel 400 Pipes & Tubes Specification

Grades : Monel 400 (UNS N04400)

Standards: ASTM, ASME and API

Specifications: ASTM B 161 / ASME SB 165

Size: Seamless 1/8″ NB to 48″ NB

Length: 3mm to 6000mm

Wall Thickness: 0.15mm and 8mm / Sch.5 to Sch. 160 & Sch. STD, Sch. XS, Sch. XXS

Type: Seamless / ERW / Welded / Fabricated / LSAW Pipes

Form: Round Pipes/Tubes, Square Pipes/Tubes, Rectangular Pipe/Tubes, Coiled Tubes, “U” Shape, Pan Cake Coils, Hydraulic Tubes

Pipe End: Plain End, Bevelled End, Treaded

Our Monel 400 Pipe & Tubes conforms to NACE MR0175/ISO 15156.

| Standard | WERKSTOFF NR. | UNS | GOST | AFNOR | JIS | BS | EN |

|---|---|---|---|---|---|---|---|

| Monel 400 | 2.4360 | N04400 | МНЖМц 28-2,5-1,5 | NU-30M | NW 4400 | NA 13 | NiCu30Fe |

| Grade | Ni | Fe | C | Mn | Si | Cu | Al | Ti | S |

|---|---|---|---|---|---|---|---|---|---|

| Monel 400 | 63.0 min | 1.0 - 2.5 | 0.30 max | 2.00 max | 0.5 max | 28.0 - 34.0 | 0.5 max | - | 0.02 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2% offset) | Elongation |

|---|---|---|---|---|

| 8.8 g/cm³ | 1350 °C (2460 °F) | Psi – 80,000 , MPa – 550 | Psi – 35,000 , MPa – 240 | 40 % |

| Types of Monel 400 Pipes & Tubes:- | |

|---|---|

| ▪ Monel 400 Precision Tubes Distributor in Egypt | ▪ Monel Alloy 400 Rectangular Tubes Trader in Peru |

| ▪ Monel 400 Seamless Pipes Supplier in Madagascar | ▪ B165 Alloy 400 Square Pipes Exporter |

| ▪ Monel UNS N04400 Seamless Tubes in Tanzania | ▪ Monel Alloy 400 Square Tubes in Chile |

| ▪ Monel DIN 2.4360 Welded Pipes Dealer in Africa | ▪ Monel Alloy 400 Hollow Pipes Supplier |

| ▪ Monel JIS NW 4400 Welded Tubes Exporter | ▪ Monel 400 Hollow Tubes Supplier in Brazil |

| ▪ Monel Alloy 400 Round Pipes Stockiest in Algeria | ▪ Monel Alloy 400 EFW Pipes Distributor in Nigeria |

| ▪ Monel Alloy 400 ERW Pipes Manufacturer in India | ▪ Monel 400 EFW Tubes Traders in Ethiopia |

| ▪ Monel Alloy 400 ERW Tubes Stockholder in Libya | ▪ Monel 400 Capillary Pipes in Ghana |

| ▪ Monel 400 Rectangular Pipes in Zambia | ▪ Monel 400 Capillary Tubes in South Africa |

| ▪ ASME SB 165 Monel 400 Alloy Pipes/Tubes | ▪ ASTM B165 Monel 400 Pipes & Tubes |

| ▪ Monel 400 B164 Round ERW Tubes Manufacturer | ▪ Monel Alloy 400 Polish Pipe Suppliers in Kuwait |

As your one-stop manufacturing partner, Sunrise Industries maintains a complete inventory of ready-to-sell raw materials alongside custom parts fabrication and full engineering services. From prototyping to production, we provide everything at a single location—serving all industrial sectors and transforming manufacturing value chains.