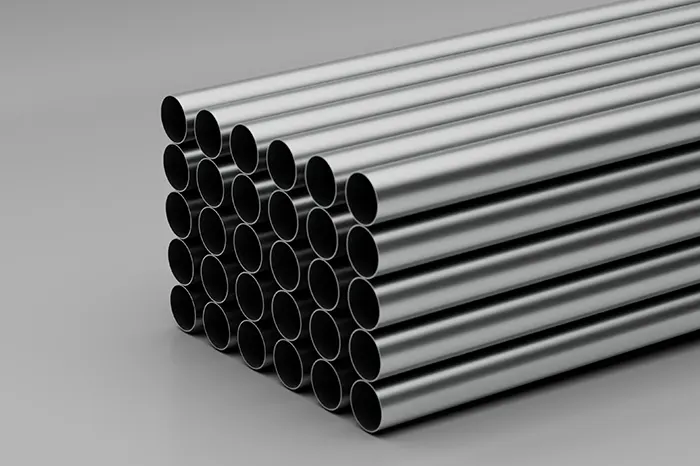

Sunrise Industries offers premium quality Nickel 201 WNR 2.4068 seamless pipes and tubes, designed as per national and international standards. These pipes provide exceptional resistance to corrosion, especially in reducing and neutral environments. Nickel 201, a low-carbon modification of Nickel 200, offers improved resistance to graphitization at elevated temperatures. Our seamless pipes and tubes are widely used in industries requiring high thermal and electrical conductivity.

They are ideal for applications such as chemical processing, marine engineering, and oil & gas. The smooth internal surface ensures efficient fluid flow, while their excellent mechanical strength guarantees long-lasting performance. We supply custom sizes and dimensions at competitive prices, catering to both domestic and international markets.

Our Nickel Alloy 201 welded pipes and tubes combine strength, durability, and corrosion resistance, making them suitable for critical applications. Manufactured from high-grade raw materials, these welded variants maintain excellent performance under varying temperature and pressure conditions. With low annealed hardness and a minimal work-hardening rate, they are perfect for deep drawing, spinning, and coining processes. The welding process ensures high-quality joints, making them reliable for transporting fluids and gases in demanding environments. These pipes and tubes are extensively used in petrochemical plants, power generation units, and marine industries. We offer customization in sizes, wall thicknesses, and finishes to meet the specific requirements of our global clientele.

Sunrise Industries supplies high-quality Nickel 201 ERW (Electric Resistance Welded) pipes known for their strength and precision. These pipes are manufactured using advanced welding technology that produces clean, uniform weld seams without filler materials. Nickel 201 ERW pipes are valued for their resistance to caustic alkalis, making them suitable for chemical processing industries. Their low carbon content minimizes carbide precipitation during welding, preserving corrosion resistance. ERW pipes are commonly used in heat exchangers, condensers, and fluid transportation systems. We provide these pipes in a range of sizes, lengths, and surface finishes, ensuring they meet the rigorous demands of our clients across various industrial sectors.

Nickel 200 Pipe & Tubes

Grades: Nickel 201 (UNS 2201)

Standards: ASTM, ASME and API

Specifications: ASTM B163, ASTM B161, ASME SB161, and ASME SB163 (Seamless)

ASTM B725, ASTM B730, ASME SB725, and ASME SB730 (Welded)

Size: Seamless 1/8″ – 10″, Welded 1/2″ – 48″

Length: 3mm to 6000mm

Wall Thickness: 0.15mm and 8mm / Sch.5 to Sch. 160 & Sch. STD, Sch. XS, Sch. XXS

Type: Seamless / ERW / Welded / Fabricated / LSAW Pipes

Form: Round Pipes/Tubes, Square Pipes/Tubes, Rectangular Pipe/Tubes, Coiled Tubes, “U” Shape, Pan Cake Coils, Hydraulic Tubes

Pipe End: Plain End, Bevelled End, Treaded

Our High Nickel N02201 Pipe & Tubes conforms to NACE MR0175/ISO 15156.

| Nickel 201 Precision Tubes Distributor in Egypt | Nickel 2201 Rectangular Tubes in Peru |

| Nickel 201 Seamless Pipes Supplier in Zambia | B161 Alloy 201 Square Pipes Exporter |

| Nickel UNS N02201 Seamless Tubes Dealers in Africa | Nickel Alloy 201 Square Tubes Trader in Ghana |

| Nickel Werkstoff Nr. 2.4068 Welded Pipes in Tanzania | Nickel Alloy 201 Hollow Pipes Supplier |

| Nickel JIS NW 2201 Welded Tubes Exporter | Ni 201 Hollow Tubes Supplier in Chile |

| Nickel Alloy 201 Round Pipes Stockiest in Algeria | Nickel 201 Alloy EFW Pipes in Nigeria |

| Nickel Alloy 201 ERW Pipes Manufacturer | Nickel 201 Alloy EFW Tubes in South Africa |

| Nickel Alloy 201 ERW Tubes Stockholder in Libya | Nickel 201 Alloy Capillary Pipes in Ethiopia |

| Nickel Alloy 201 Rectangular Pipes in Madagascar | Nickel 201 Capillary Tubes in Brazil |

| ASME SB 161 Nickel 201 Alloy Pipes/Tubes | ASTM B161 Nickel 201 Pipes & Tubes |

| Nickel 201 B163 Polished Pipes in Ajman | Nickel 201 Rectangle Pipes Exporter in UAE |

| Standard | WERKSTOFF NR. | UNS | GOST | AFNOR | JIS | BS | EN |

|---|---|---|---|---|---|---|---|

| Nickel 201 | 2.4068 | N02201 | НП-2 | - | NW 2201 | NA 12 | Ni 99 |

| Grade | Ni | Fe | C | Mn | Si | Cu | Mg | Ti | S |

|---|---|---|---|---|---|---|---|---|---|

| Nickel 201 | 99.0 min | 0.4 max | 0.02 max | 0.35 max | 0.2 max | 0.25 max | 0.15 max | 0.1 max | 0.01 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2% Offset) | Elongation |

|---|---|---|---|---|

| 8.9 g/cm³ | 1446°C (2635°F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45% |

As your one-stop manufacturing partner, Sunrise Industries maintains a complete inventory of ready-to-sell raw materials alongside custom parts fabrication and full engineering services. From prototyping to production, we provide everything at a single location—serving all industrial sectors and transforming manufacturing value chains.