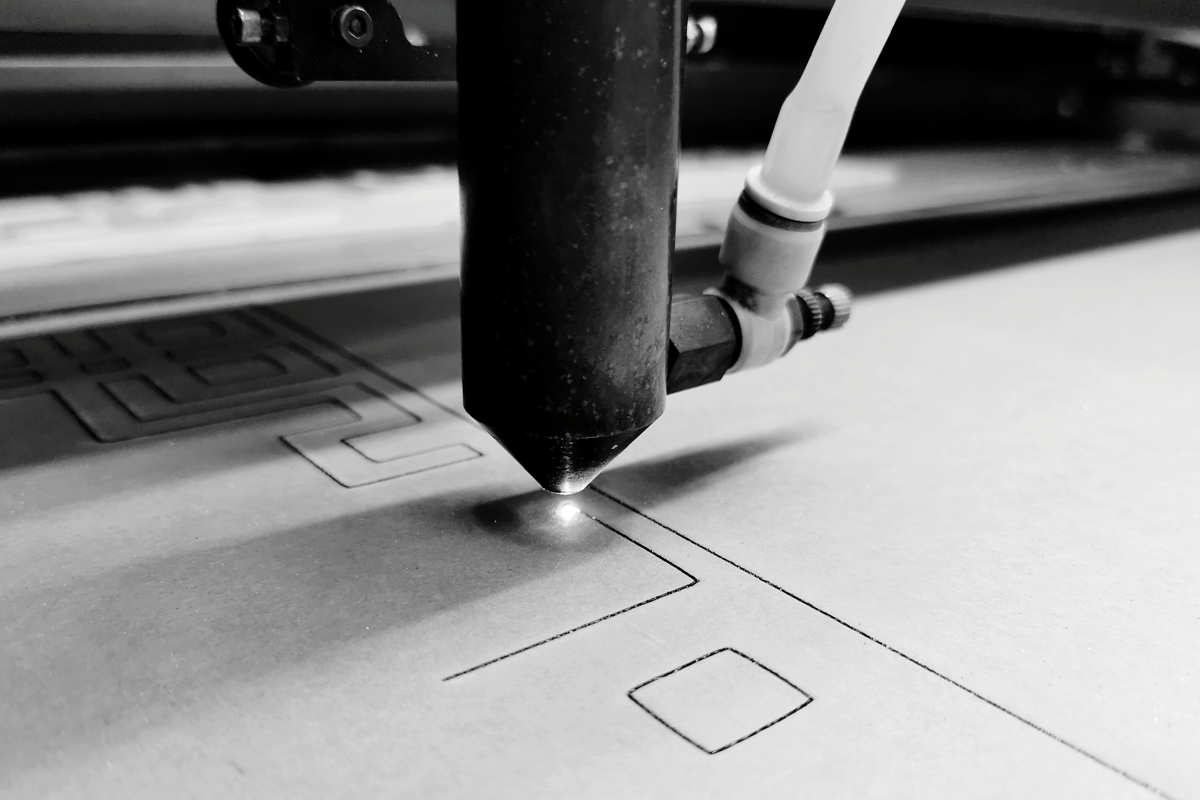

Commonly accepted file types include 2D DXF files for flat patterns and 3D CAD files such as STEP, IGES, or STL for added context or reference. DXF is the most preferred format for laser and waterjet cutting.

As your one-stop manufacturing partner, Sunrise Industries maintains a complete inventory of ready-to-sell raw materials alongside custom parts fabrication and full engineering services. From prototyping to production, we provide everything at a single location—serving all industrial sectors and transforming manufacturing value chains.