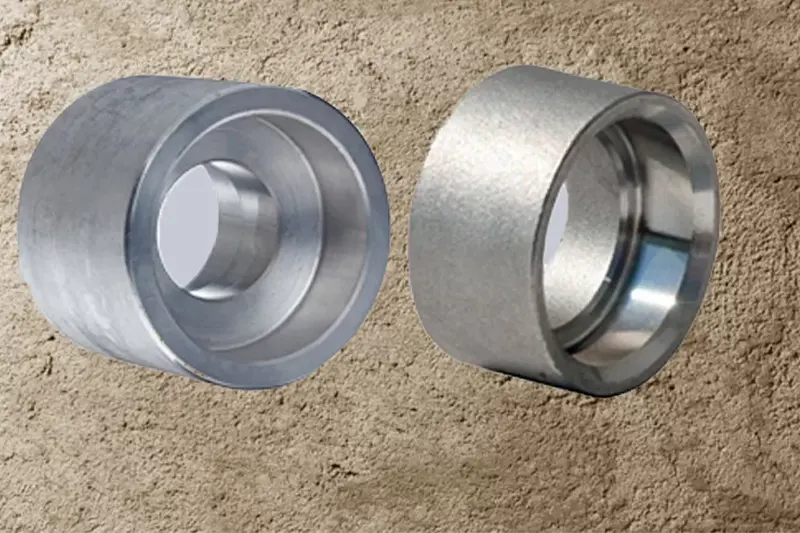

Stainless Steel Socket Weld Reducers, ASTM A182 Forged Full Reducers, and SS Forged Concentric Reducers are widely used in industrial piping systems to connect pipes of different diameters. These fittings ensure a smooth transition between pipe sizes, maintaining proper flow and reducing turbulence. They are manufactured from high-quality stainless steel, carbon steel, duplex steel, super duplex, and high nickel alloys to provide durability, strength, and excellent resistance to corrosion.

Carbon Steel Forged Concentric Reducers are in high demand across regions like Qatar and the Middle East due to their high-pressure handling capacity and long service life. ASME B16.11 Concentric Reducers and Alloy Steel Forged Reducers are preferred in industries such as oil & gas, petrochemical, chemical processing, and power generation. High Nickel Alloy Threaded Reducers and Duplex Steel Reducing Reducers are ideal for marine and offshore environments where superior corrosion resistance is critical.

Forged reducers are also known as repair couplings or condensed couplings, especially when they are used to join pipes of dissimilar sizes. These fittings can be fixed anywhere along the pipeline to prevent leaks or to repair damaged sections. They are manufactured with precise dimensions, ensuring perfect alignment, leak-proof connections, and reliable performance in industrial piping networks.

Different material grades such as Super Duplex, Nickel Alloy, Hastelloy, and Alloy Steel are used to meet specific application requirements. Nickel Alloy Forged Reducers and Hastelloy Forged Reducers are widely exported to countries like Saudi Arabia and Qatar. Stainless Steel Socket Weld Reducers and Alloy Steel Forged Full Reducers provide enhanced strength and durability even in high-pressure and high-temperature conditions.

These forged reducers are available in customized sizes, shapes, and specifications to suit various project needs. They are exported to multiple countries, including Qatar, Bahrain, Saudi Arabia, Indonesia, United States, Singapore, Malaysia, Turkey, UAE, Russia, Ukraine, South Africa, and Australia. The product range also includes Duplex Socket Weld Concentric Reducers, MSS SP-79 Reducers, and Inconel Forged Reducers, offering reliable solutions for complex industrial piping systems.

Socket Weld Reducer

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F904L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C

ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200), UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400), UNS 8020 (ALLOY 20 / 20 CB3), UNS 8825 (INCONEL 825), UNS 6600 (INCONEL 600), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276).

Socket Weld Reducers are available in sizes ranging from 1/4″ NB to 4″ NB, making them ideal for connecting pipes of different diameters in various industrial piping systems. They are manufactured in accordance with ASTM A182 and ASTM SA182 standards, ensuring high strength, durability, and resistance to corrosion. Dimensional accuracy is maintained as per ASME 16.11, MSS SP-79, MSS SP-95, MSS SP-83, MSS SP-97, and BS 3799, ensuring a precise and secure fit in critical applications.

These reducers are offered in different pressure classes, including 2000 LBS, 3000 LBS, 6000 LBS, and 9000 LBS, suitable for a wide range of operating conditions. They are available in Socket Weld and Screwed-Threaded connections like NPT, BSP, and BSPT for easy installation. The product range includes Concentric Reducers, Eccentric Reducers, and Caps, providing versatile solutions for pipeline transitions and closures.

Socket Weld Reducers are available in sizes from 1/4″ NB to 4″ NB, making them suitable for connecting pipes of varying diameters. They are manufactured as per ASTM A182 and ASTM SA182 standards, ensuring superior strength and corrosion resistance. The dimensions are maintained according to ASME 16.11, MSS SP-79, MSS SP-95, MSS SP-83, MSS SP-97, and BS 3799, providing a precise fit for reliable pipeline performance.

These reducers are designed for pressure classes 2000 LBS, 3000 LBS, 6000 LBS, and 9000 LBS, meeting diverse industrial requirements. They come in Socket Weld and Screwed-Threaded types like NPT, BSP, and BSPT. The range includes Concentric Reducers, Eccentric Reducers, and Caps, offering versatile solutions for smooth pipeline transitions and secure closures.

As your one-stop manufacturing partner, Sunrise Industries maintains a complete inventory of ready-to-sell raw materials alongside custom parts fabrication and full engineering services. From prototyping to production, we provide everything at a single location—serving all industrial sectors and transforming manufacturing value chains.