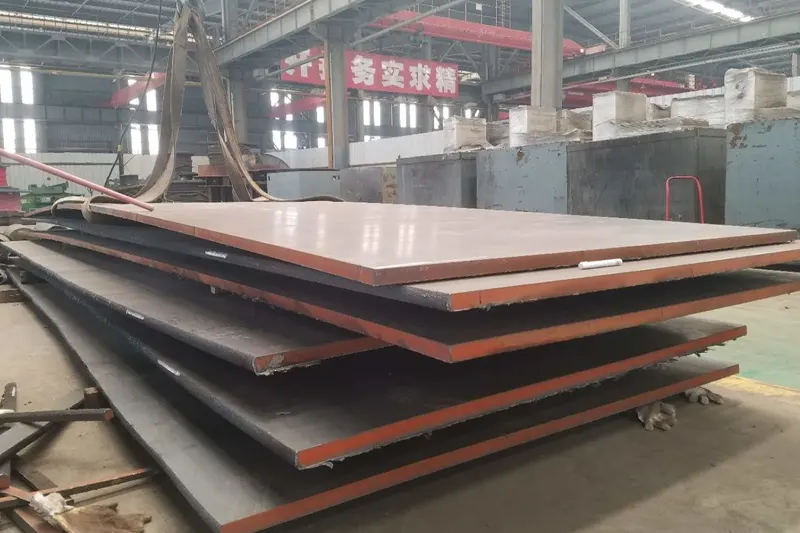

Stainless Steel Beams are strong, durable structural elements widely used in construction and industrial projects. Designed in I, H, and T shapes, these beams provide excellent load-bearing capacity and resistance to deformation. Their corrosion resistance and strength make them ideal for both indoor and outdoor applications, especially in harsh environments where long service life is essential.

Stainless steel beams are available in several grades such as SS 304, 316, and 310, depending on the level of corrosion resistance and temperature performance needed. SS 304 beams are most commonly used for general-purpose structural work, while SS 316 is preferred for marine and chemical environments. These beams are typically produced in hot-rolled or laser-fused forms, ensuring precision and uniformity.

Stainless steel beams are used in a variety of industries, including construction, shipbuilding, petrochemical plants, bridges, tunnels, and power generation facilities. Their ability to carry heavy loads while resisting rust, chemicals, and heat makes them suitable for frameworks, platforms, bridges, and supporting columns. In architectural design, they are also chosen for their clean finish and modern appearance.

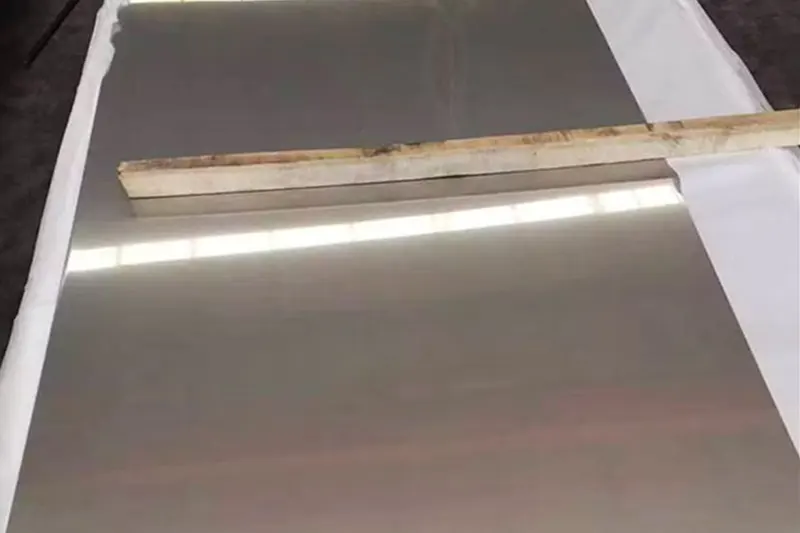

Available in different surface finishes like mill, polished, and brushed, stainless steel beams can be further fabricated as per specific project requirements. They can be cut, drilled, welded, or machined easily, making them a flexible material choice for complex construction designs. Custom lengths, sizes, and finishes can be provided to ensure seamless installation and maximum strength.

At Sunrise Industries, we supply top-grade stainless steel beams with tight dimensional tolerances and strict adherence to ASTM and EN standards. We maintain ready stock in various sizes and offer customized solutions with fast delivery across India and overseas. With a focus on quality, reliability, and customer satisfaction, we are a trusted source for structural stainless steel products.

Stainless Steel Beams

ASTM A276, ASTM A484 SS 201, 202, 301, 302, 303, 304, 304H, 304L, 316, 316H, 316L, 309, 309S, 310, 310S, 316Ti, 317, 317L, 347, 321, 321H, 410, 416, 420, 430, 430F, 431, 440C, 630, 17-4PH, F51.

ASTM / ASME A815 UNS No. S31803, UNS No.S32205, UNS No.S31254, UNS No.S31550, UNS No.S32750, UNS No. S32760

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200), UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400), UNS 8020 (ALLOY 20 / 20 CB3), UNS 8825 (INCONEL 825), UNS 6600 (INCONEL 600), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276).

ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 (CU -NI- 90/10), C 71500 (CU -NI- 70/30)

Stainless Steel Beams are designed to deliver exceptional structural support with precise dimensions and long-term durability. Manufactured from premium stainless steel grades like 304, 316, and 310, these beams are engineered to resist corrosion, withstand heavy loads, and perform reliably in demanding environments. Whether used in industrial infrastructure, bridges, or architectural frameworks, they offer a perfect balance of strength, performance, and low maintenance. Precision fabrication and adherence to global standards make these beams a trusted choice for high-performance structural applications.

Stainless Steel Beams offer unmatched strength, corrosion resistance, and stability in structural frameworks. Designed in I-Beam, H-Beam, and T-Beam profiles, these beams are widely used in construction, marine, oil & gas, and heavy engineering industries. Their robust performance in extreme environments makes them ideal for long-term infrastructure proje

Available in high-quality stainless steel grades such as 304, 316, and 310, these beams are manufactured with precise dimensions and superior surface finishes. Whether it’s for high-temperature, corrosive, or load-bearing applications, Stainless Steel Beams provide reliable structural integrity and easy fabrication for customized needs.

As your one-stop manufacturing partner, Sunrise Industries maintains a complete inventory of ready-to-sell raw materials alongside custom parts fabrication and full engineering services. From prototyping to production, we provide everything at a single location—serving all industrial sectors and transforming manufacturing value chains.