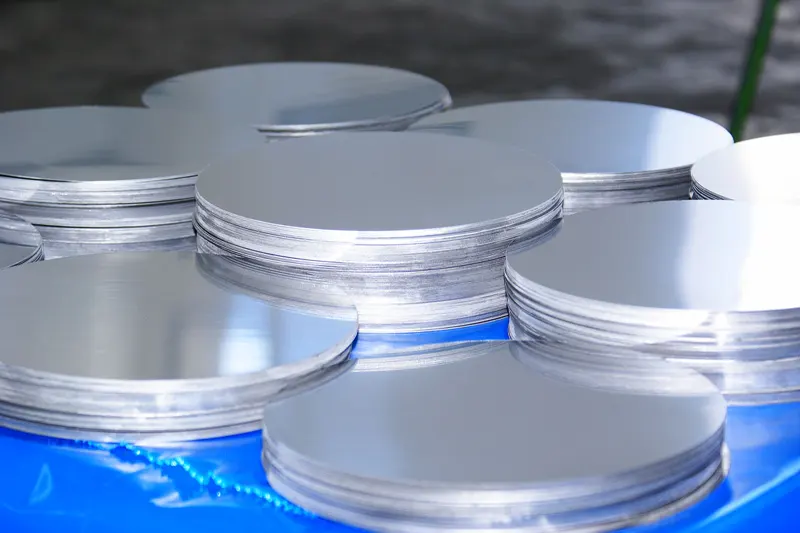

We provide premium-quality 304 Stainless Steel Circles and 316 Stainless Steel Round Discs in finishes such as 2D, BA, 2B, and 8K. Stainless steel circles are essentially plates or sheets manufactured in a circular form, with thickness ranging from 1mm to 100mm. Depending on the grade used, their chemical composition and physical properties may vary, making them suitable for diverse applications. Known for high strength, corrosion resistance, and durability, these circles are widely used in industries such as automotive, petrochemical, construction, and fabrication. Available in multiple finishes, stainless steel circles not only deliver outstanding performance but also ensure an aesthetic appearance, making them a popular choice for industrial as well as decorative applications.

With a strong distribution network and ready stock availability, we ensure timely delivery across India and overseas. Our commitment to quality, competitive pricing, and customer-centric service has earned us the trust of hundreds of clients. Choose Sunrise Industries for polished stainless steel circles that meet the highest standards in strength, finish, and reliability.

Using stainless steel circles and round discs provides multiple benefits across industries. Their performance, durability, and versatility make them an essential choice for manufacturers and engineers. Some of the key advantages include:

As your one-stop manufacturing partner, Sunrise Industries maintains a complete inventory of ready-to-sell raw materials alongside custom parts fabrication and full engineering services. From prototyping to production, we provide everything at a single location—serving all industrial sectors and transforming manufacturing value chains.